Geometrical Parameters & Condition Assessment

We provide precision verification and correction of equipment, structures, skids, piping interfaces, and rotating machinery to meet design and OEM tolerances.

Provides accurate inspection of geometrical parameters such as flatness, verticality, concentricity, and cylindricity

Enables early detection of wear, misalignment, or deviations

Prevents minor issues from escalating into costly failures

3D Measurement for Installation Assistance

We conduct pre- and post-installation dimensional checks to ensure first-time-right assembly, reducing site rework and project delays.

Uses laser-based 3D metrology to guide equipment and machinery installation

Ensures accurate fit-up during installation.

Reduces rework and installation errors

Speeds up the commissioning process

Brownfield Reference Capture & Benchmarking

We validate dimensions of existing assets before modification, expansion, or retrofitting to ensure seamless integration with new equipment.

Captures and preserves existing reference points

Installs new, robust benchmarks tied to absolute coordinates

Ensures consistency and reliability for all future measurements

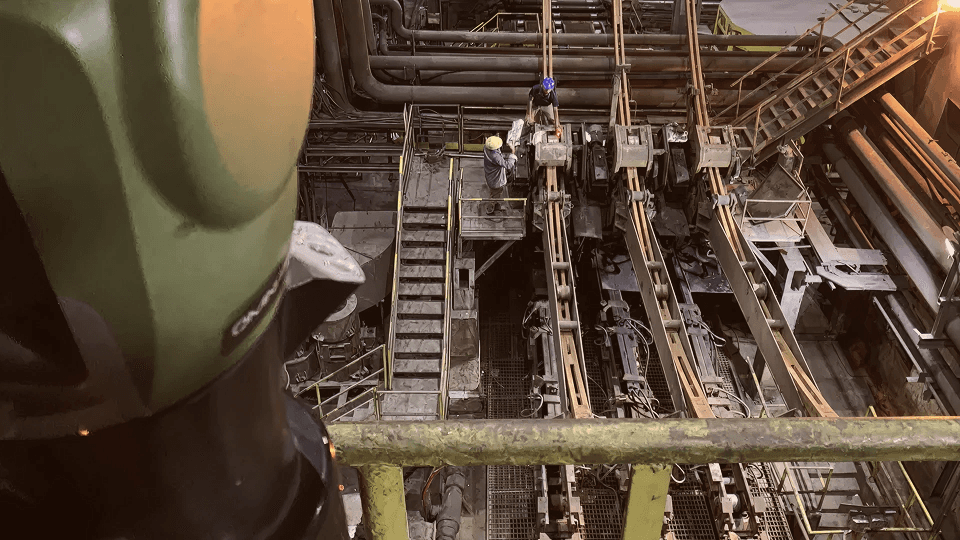

Alignment & Installation of Critical Components

We conduct high-quality dimensional inspections during shutdowns to support maintenance, replacement, and realignment within tight outage windows.

Implements streamlined dimensional control for critical alignments during erection.

Provides real-time guidance throughout the installation process

Reduces crane time and minimizes shutdown duration

Ensures precise and accurate installation

Design Validation

We perform dimensional verification during Front End Engineering Design (FEED) and EPC stages to confirm constructability and prevent downstream clashes.

Validation of design intent, interfaces, and tolerances to ensure constructible, clash-free layouts

Early identification of dimensional conflicts and clearance issues before execution

Integration of as-is dimensional data for accurate brownfield FEED and EPC planning

Reduction of site rework, delays, and cost overruns through proactive dimensional checks

Improved FEED maturity and EPC execution readiness with data-driven verification

(07)

Why Choose SixD for Dimension Engineering?

Proven Domain Expertise

Decades of experience across power, oil & gas, metals, and heavy industries, with execution insight across FEED, EPC, commissioning, and brownfield projects.

OEM & Standards Compliance

All dimensional activities follow OEM tolerances and international standards, ensuring design intent from engineering through operation.

Flexible On-Site Execution

Portable precision systems enable accurate measurements in live plants and shutdowns with minimal operational disruption.

High-Precision Accuracy

Advanced metrology delivers accurate, auditable dimensional data for large-scale and critical assets.

End-to-End Control

Complete support from benchmarking and design validation to alignment and final acceptance.

Lifecycle Value

Reduced rework, downtime, and lifecycle cost, supported by future-ready digital dimensional data.