Chemicals & Process

(01)

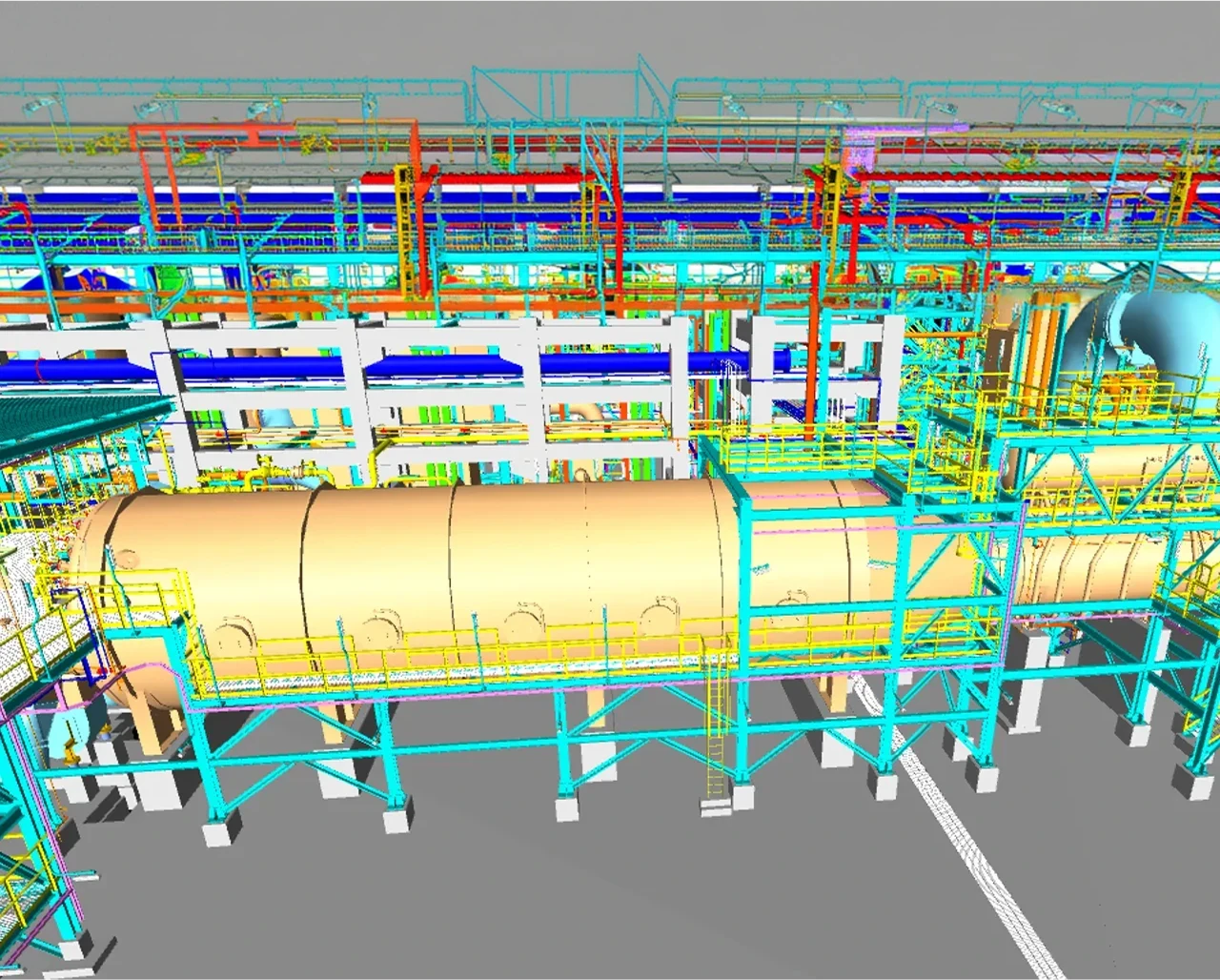

Safety, compliance, and operational reliability are essential in chemicals, specialty chemicals, fertilizers, and process plants. SixD provides engineering-led digital solutions such as as-built digitization, owner’s engineering, dimension engineering, reverse engineering, EPC design validation, and digital twin enablement to ensure accurate execution and lifecycle integrity in safety-critical environments.

(02)

(02)

Engineered Asset Control

Chemical and process plants face high pressure, corrosive environments, strict regulations, and continuous production demands. Undocumented modifications, outdated drawings, or dimensional deviations can cause safety incidents, compliance violations, production losses, and unplanned shutdowns.

To stay competitive and compliant, the chemicals and process industry must use verified engineering data, independent technical oversight, and intelligent digital systems rather than assumptions.

SixD leverages process-industry engineering expertise and advanced digitization technologies to deliver reliable, consistent results for greenfield, brownfield, and retrofit projects.

(02)

Resolving Critical Bottlenecks Across

Resolving Critical Bottlenecks Across

1

Chemicals

Outdated drawings, undocumented modifications, and compliance gaps increase safety and operational risks. SixD provides engineering-grade as-built digitization, owner’s engineering, and digital twins to ensure safe execution, regulatory compliance, and digitally traceable chemical plant operations.

2

Specialty Chemicals

Tight tolerances, frequent changeovers, and inconsistent data limit process efficiency. SixD uses precision dimension engineering, high-accuracy measurement, and digital asset intelligence to enable reliable scale-up, consistent quality, and future-ready specialty chemical manufacturing.

3

Fertilizers

Corrosive environments, alignment drift, and aging assets decrease plant availability. SixD offers precision alignment, reverse engineering, and lifecycle-ready as-built documentation to improve uptime, extend equipment life, and support sustainable fertilizer production.

4

Process Plants

Complex piping, interface mismatches, and constructability risks cause project and revamp delays. Provides FEED–EPC validation, constructability reviews, digital as-built models, and digital twins to ensure predictable execution and Industry 5.0-ready process facilities.

(03)

Trusted by Innovators Industry Leaders

(03)

Trusted by Innovators Industry Leaders

(04)

How SixD Adds Value to Chemicals & Process Assets

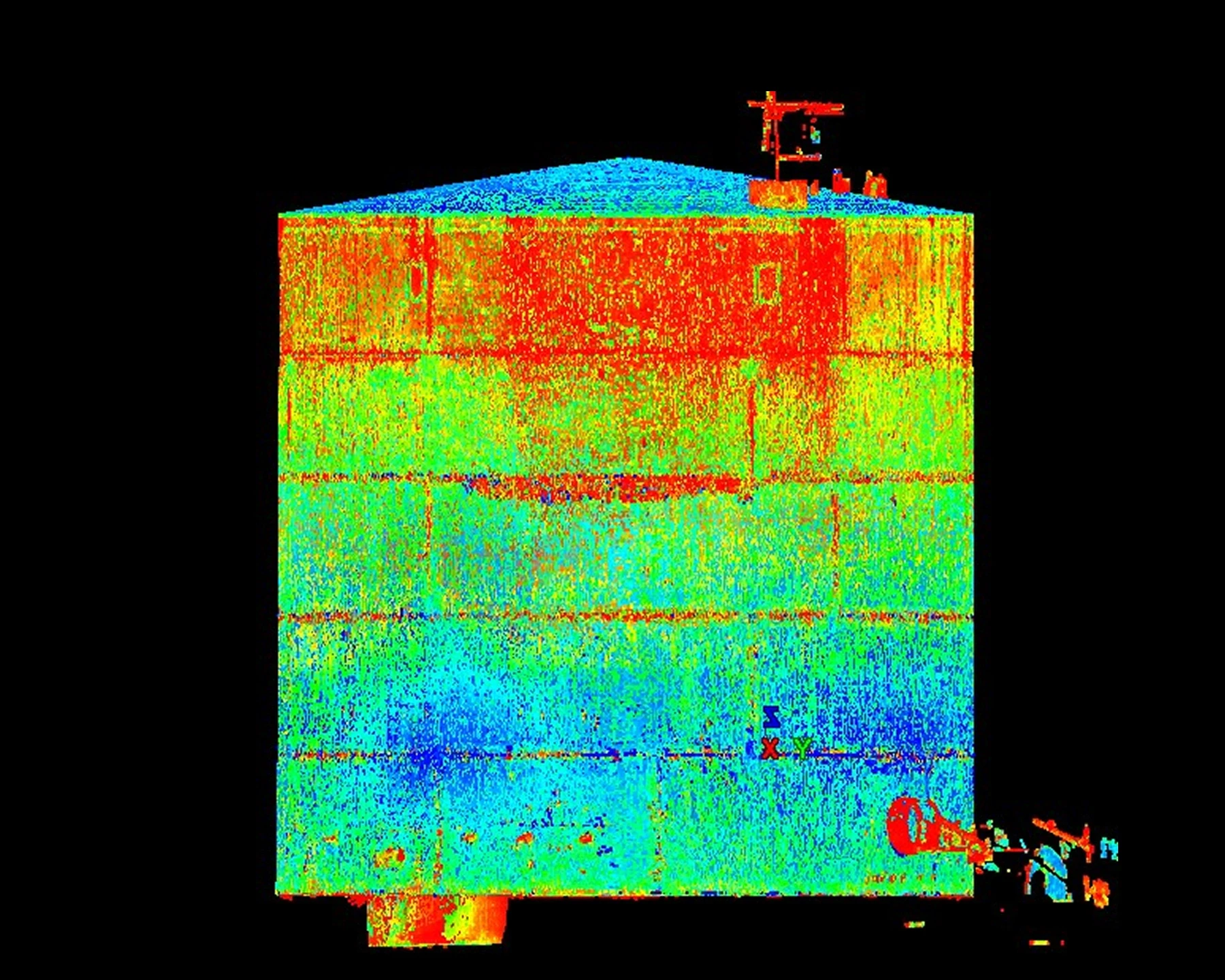

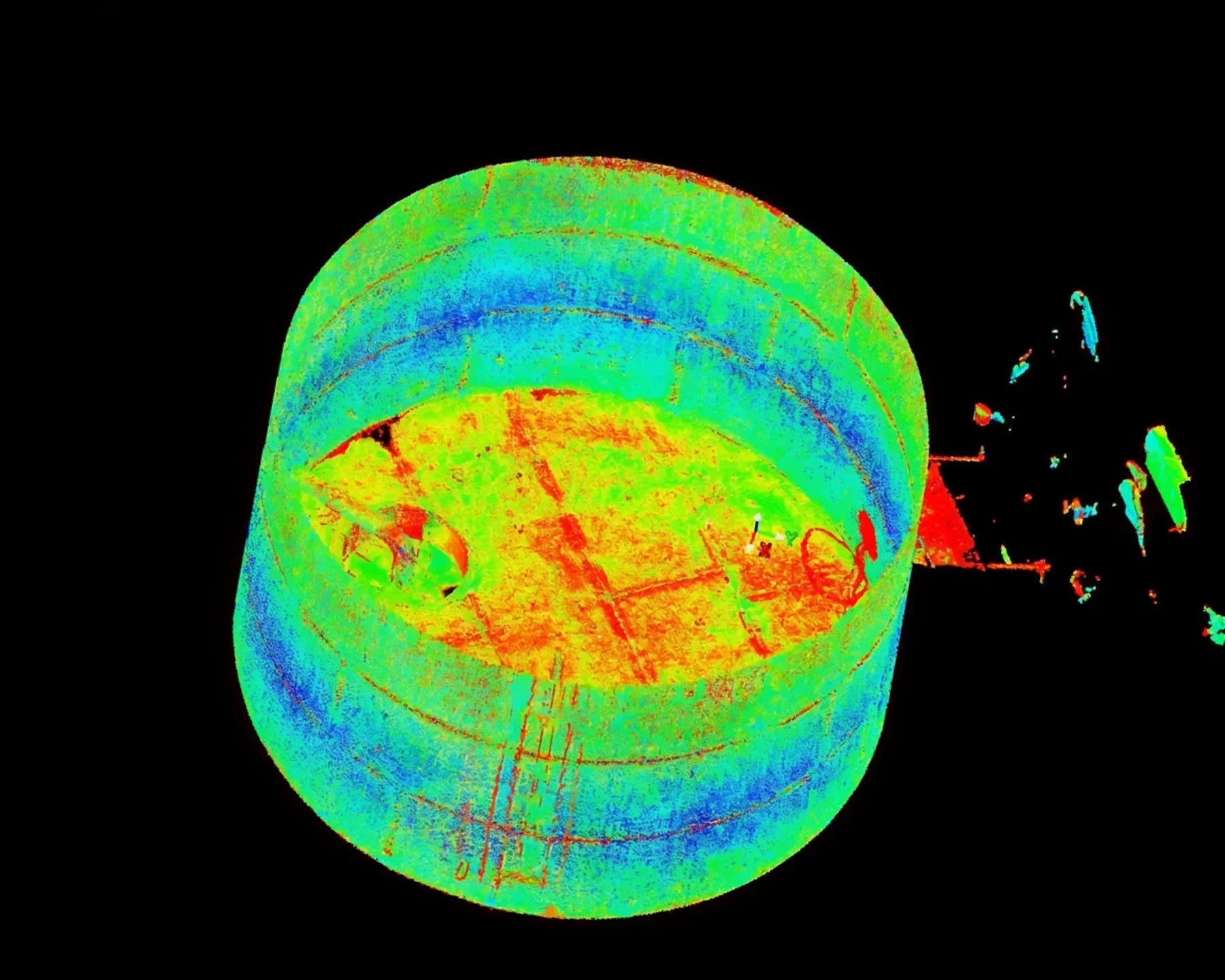

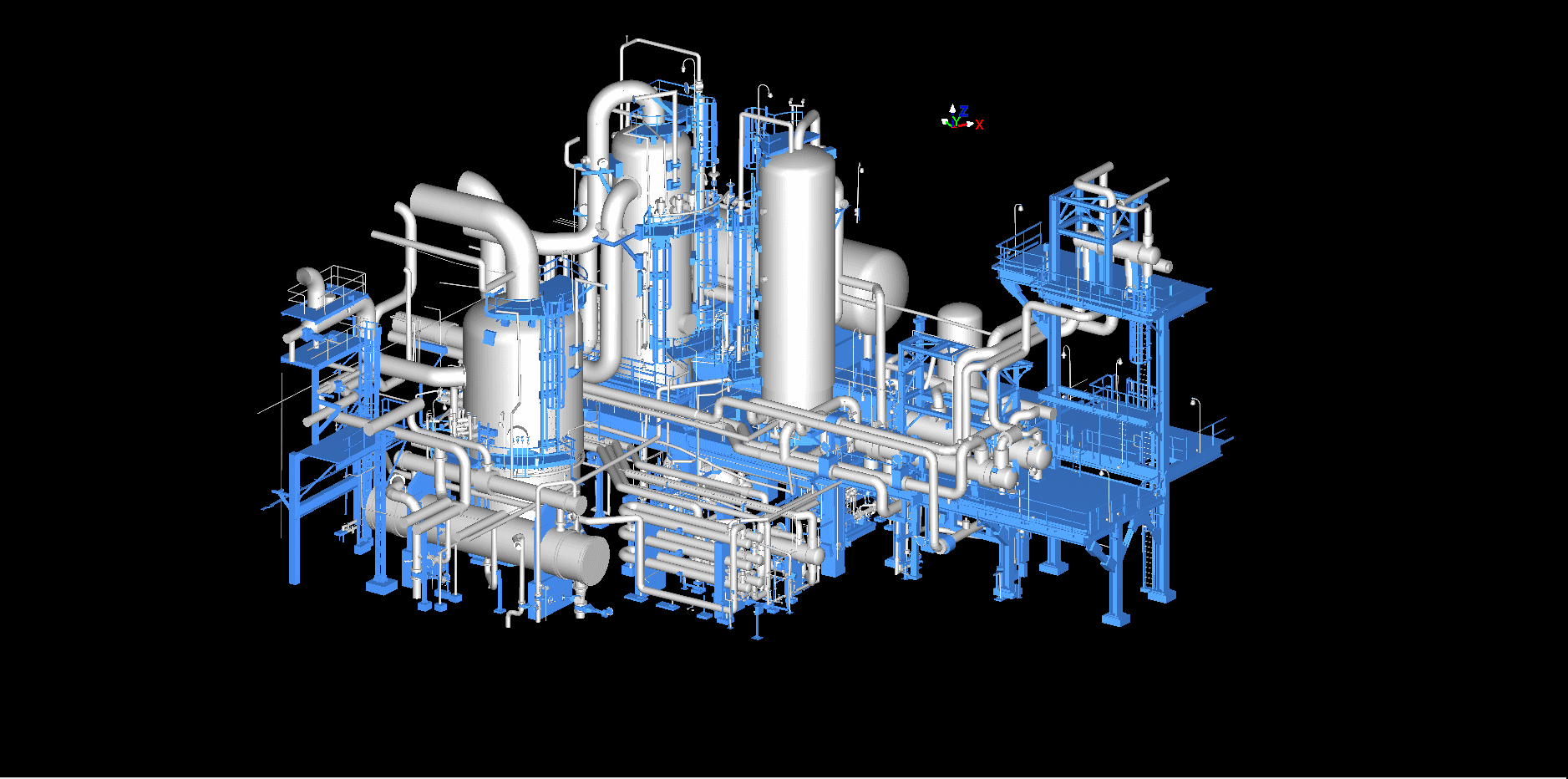

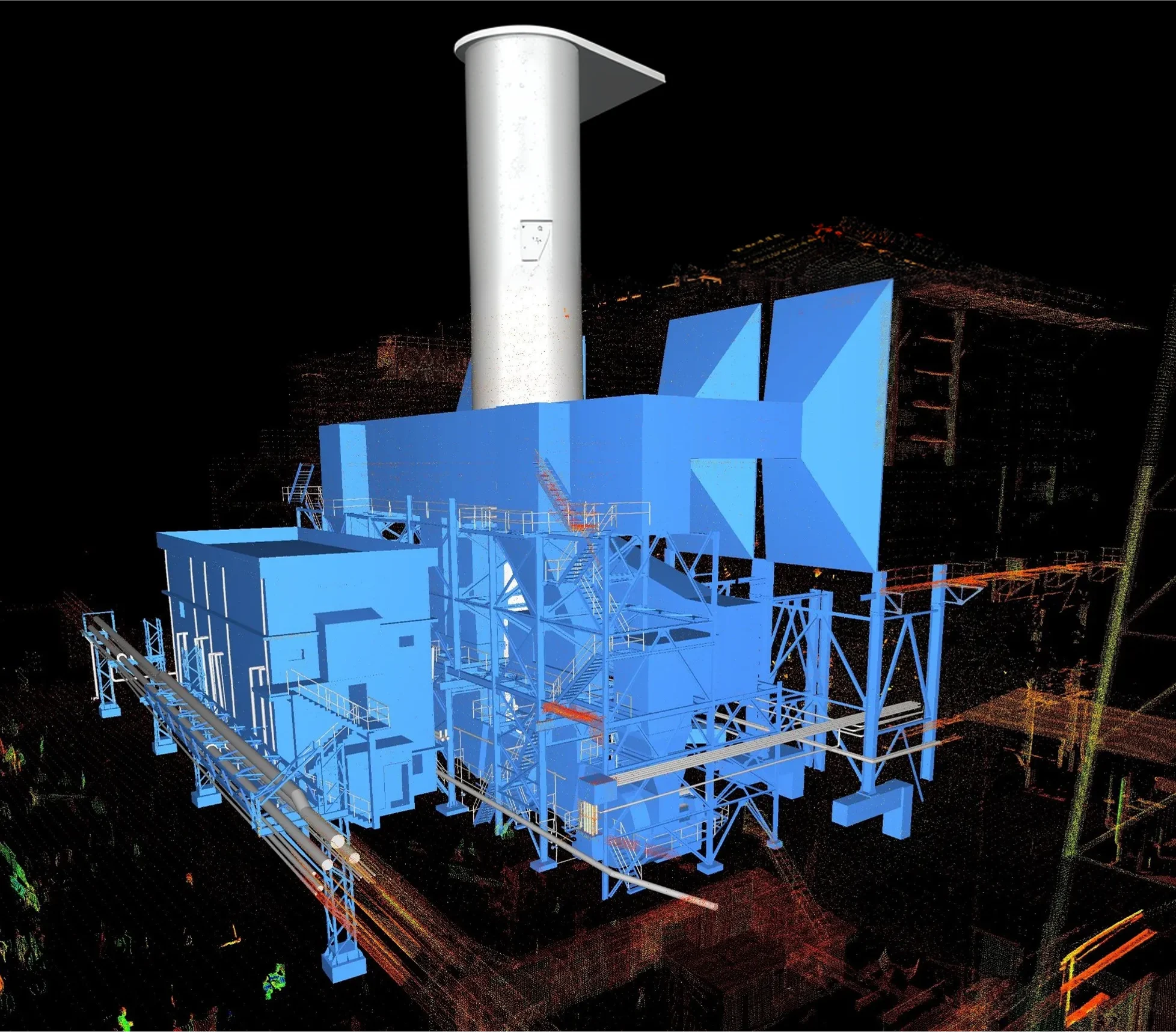

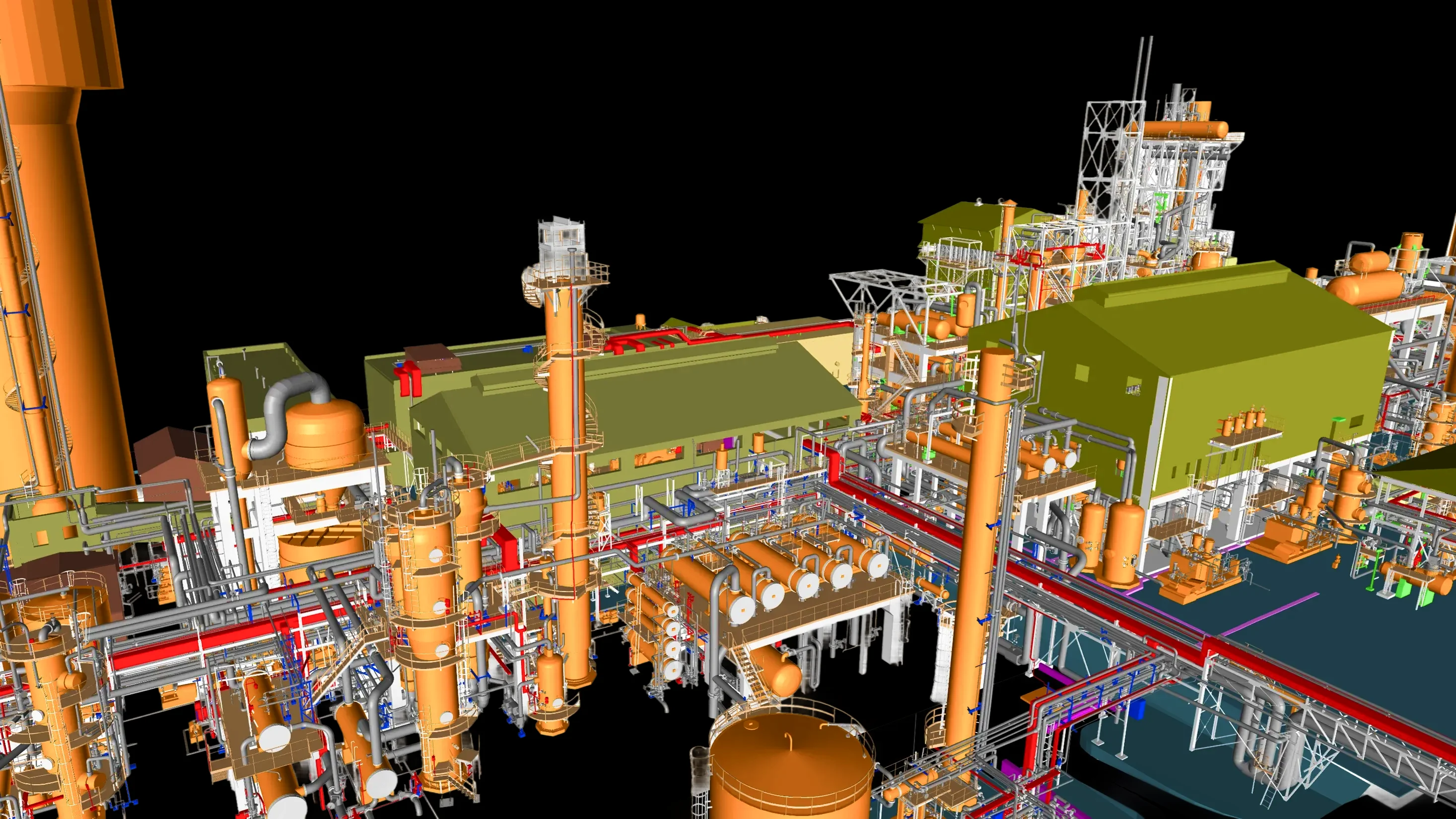

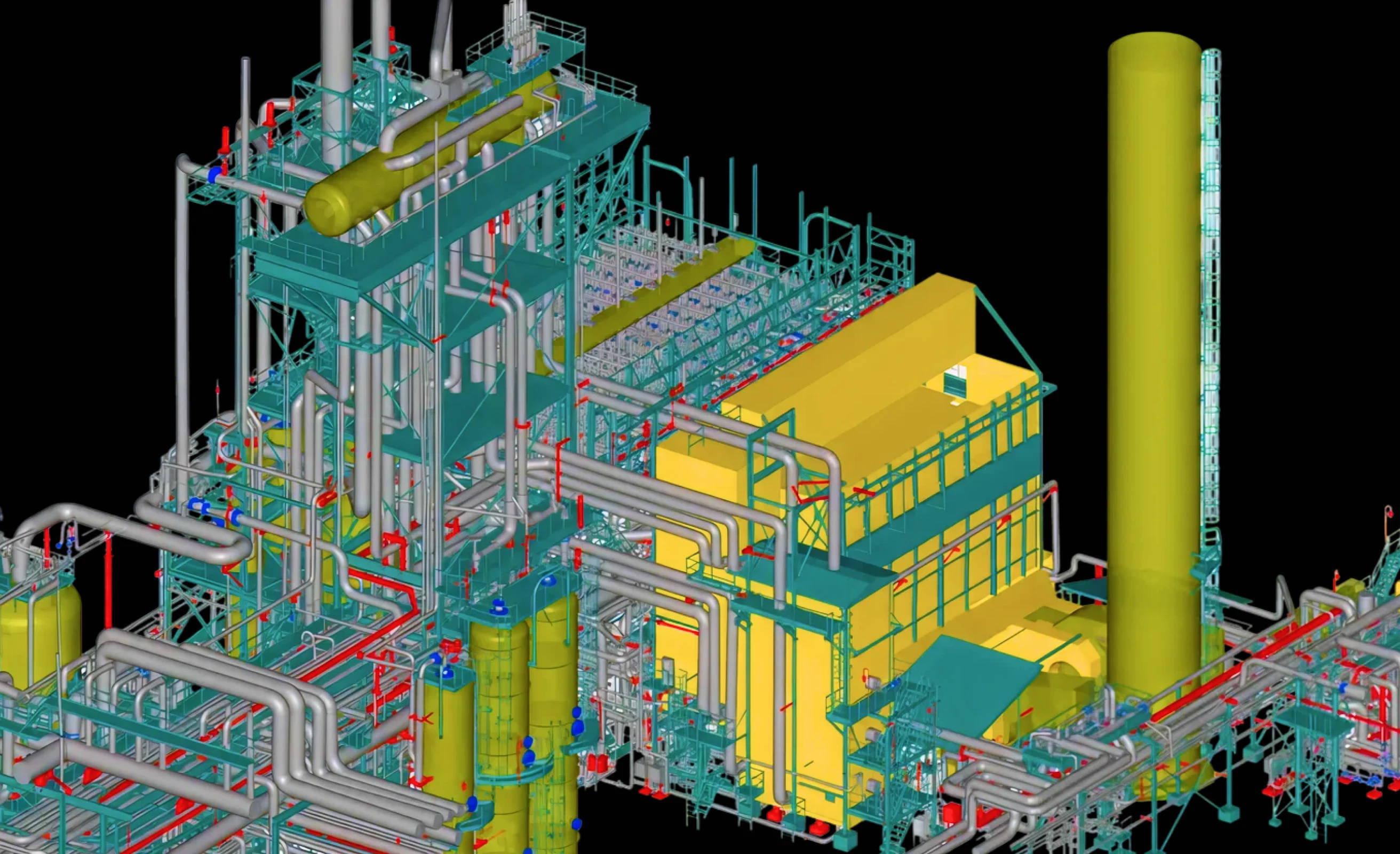

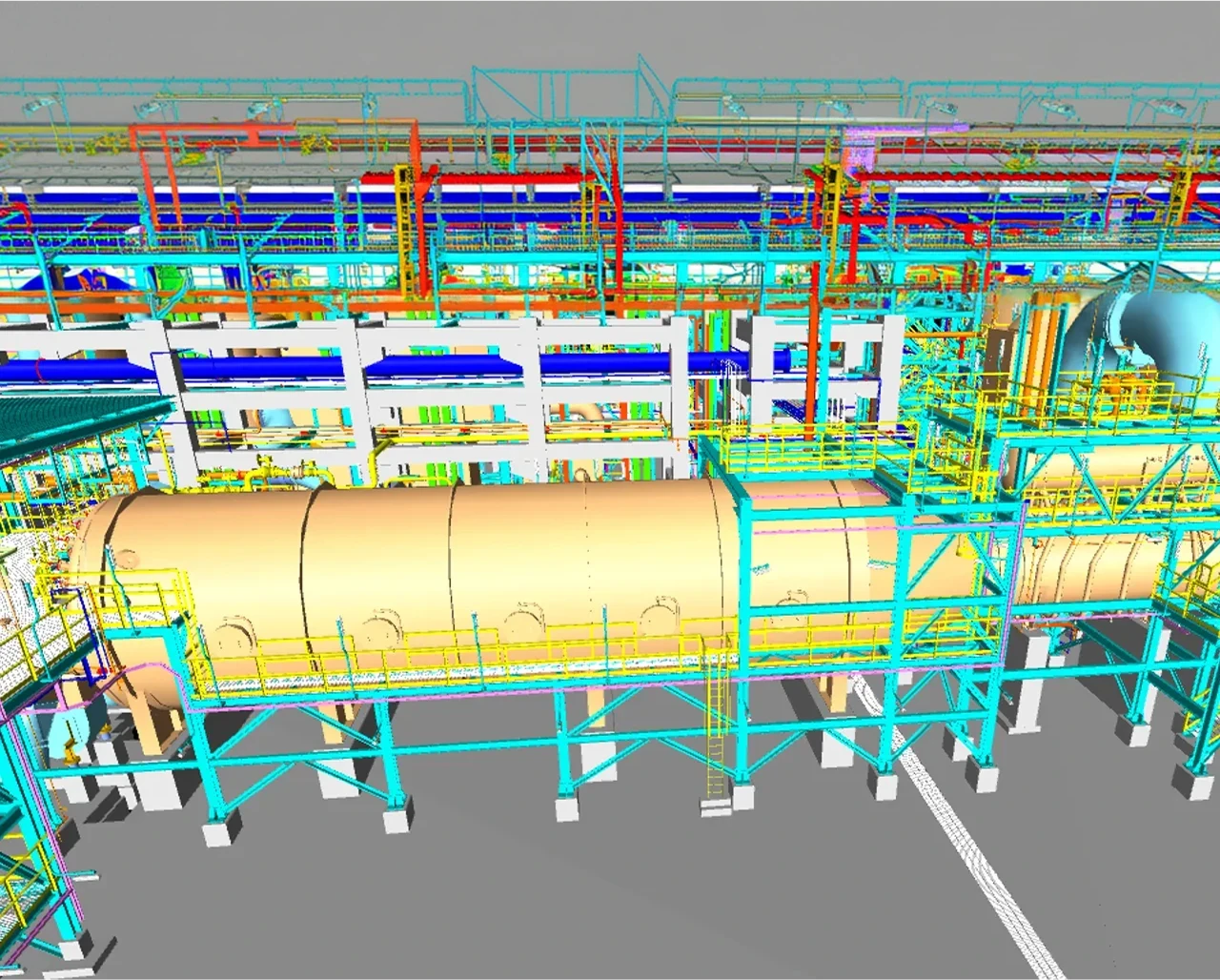

As-Built Engineering & Process Plant Digitization

SixD provides high-accuracy 3D laser scanning and intelligent as-built models for reactors, piping networks, storage systems, utilities, and balance-of-plant, creating a single source of truth for engineering, safety reviews, and future modifications.

Independent Technical Oversight

As an independent Owner’s Engineer, SixD safeguards design intent, validates EPC deliverables, and ensures compliance with codes, standards, and safety requirements throughout FEED, EPC, construction, and commissioning phases.

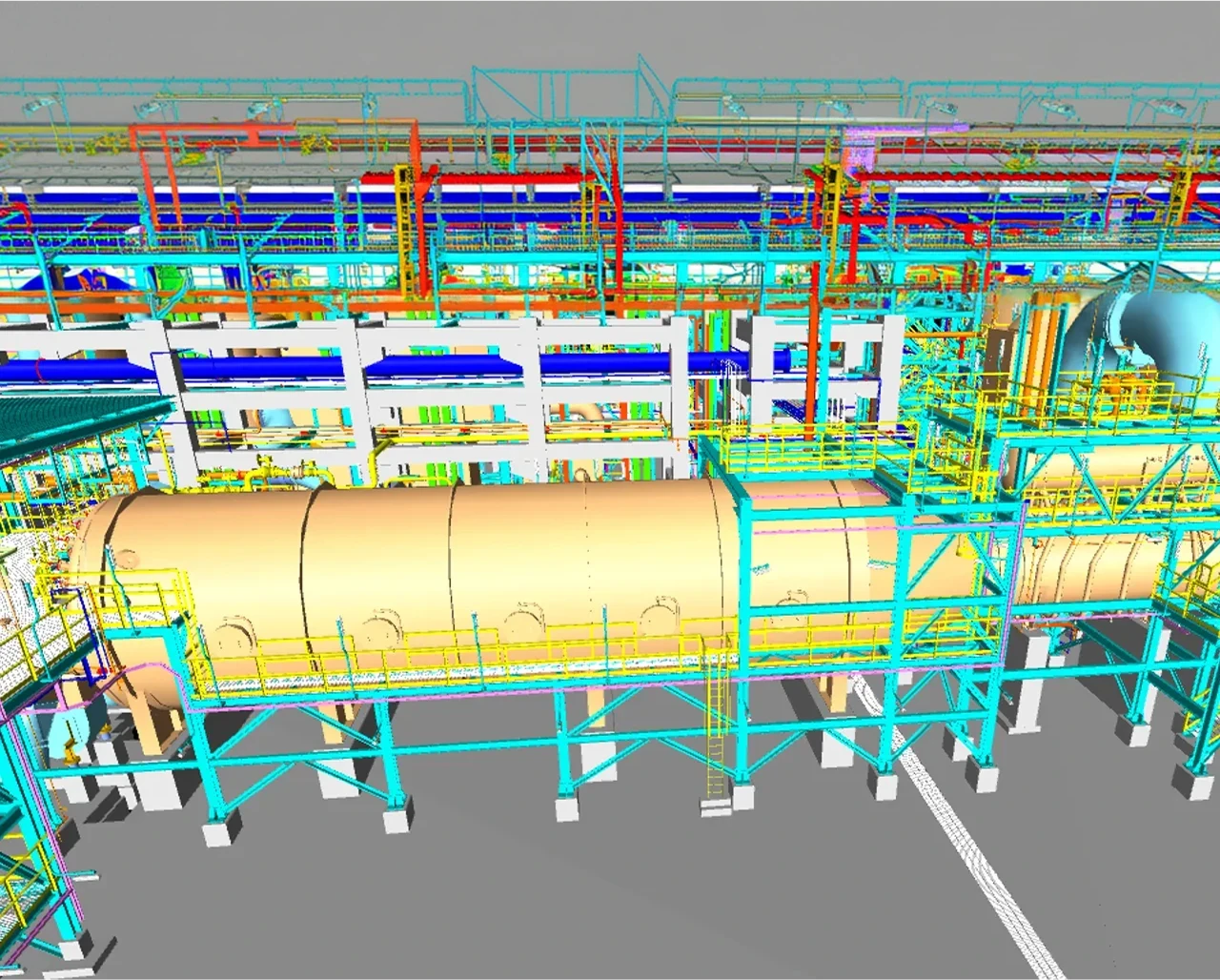

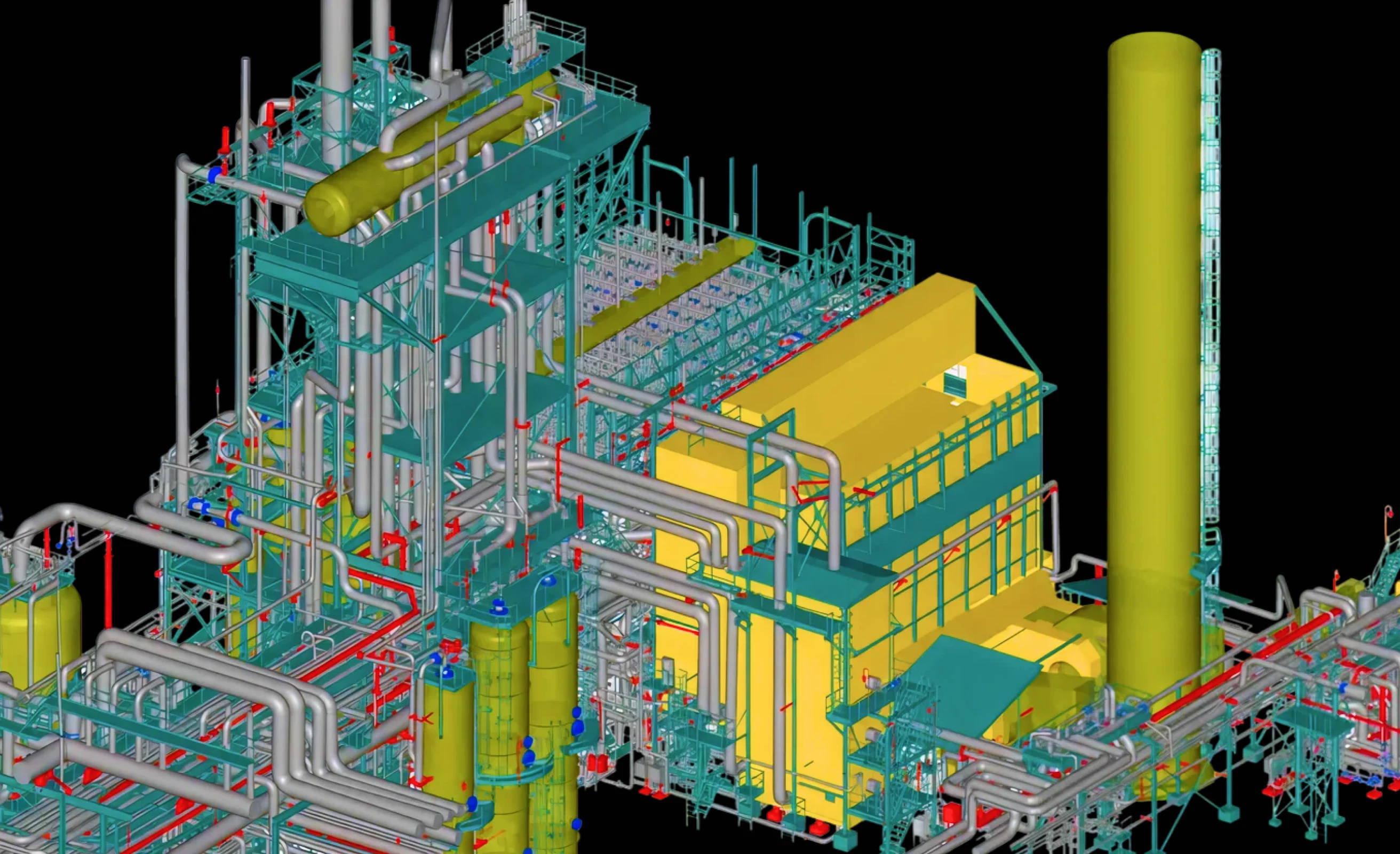

FEED–EPC Design Validation & Constructability Assurance

We validate FEED and EPC designs against actual site conditions, identifying constructability gaps, interface mismatches, and safety risks early to reduce rework, delays, and execution uncertainty.

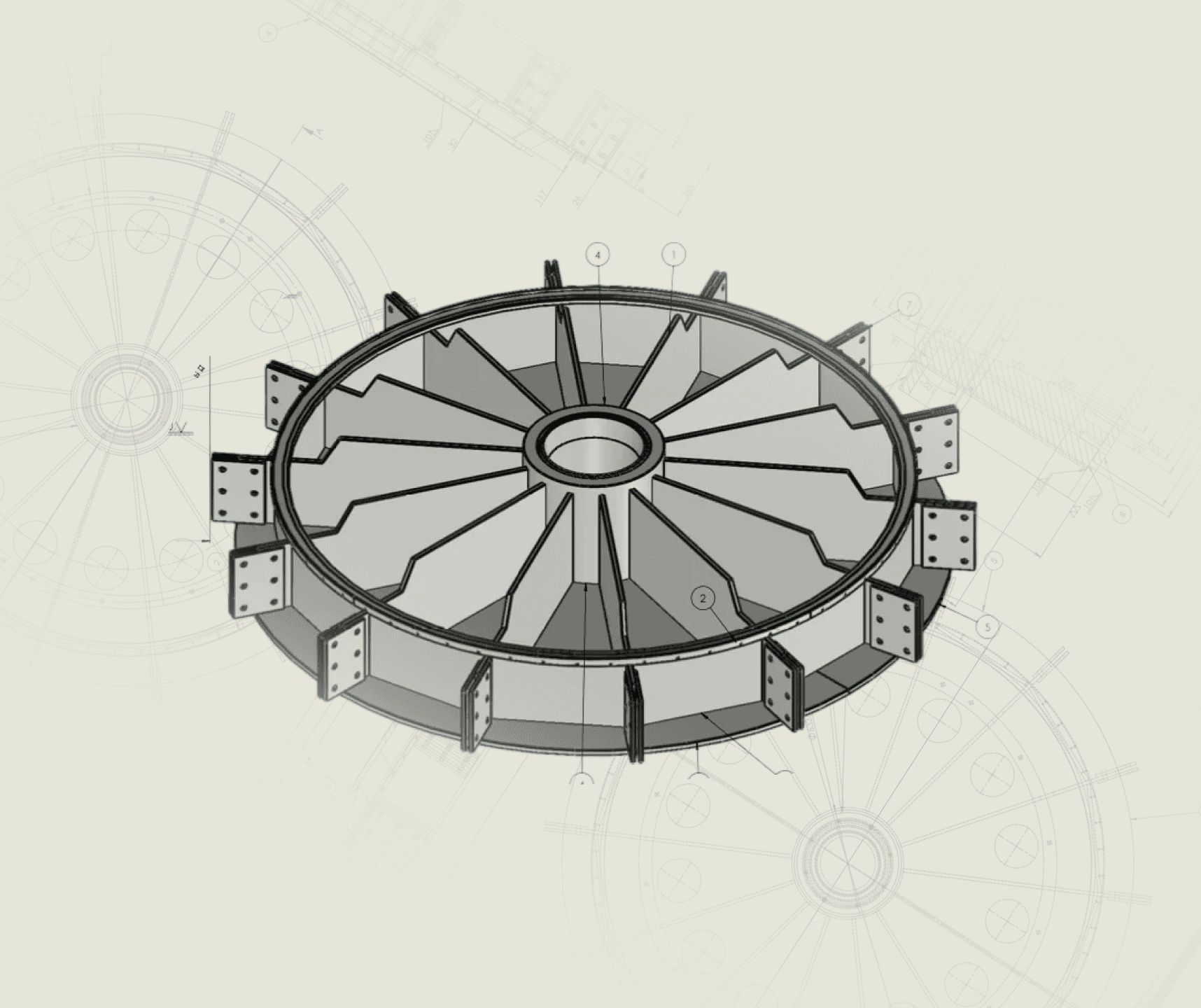

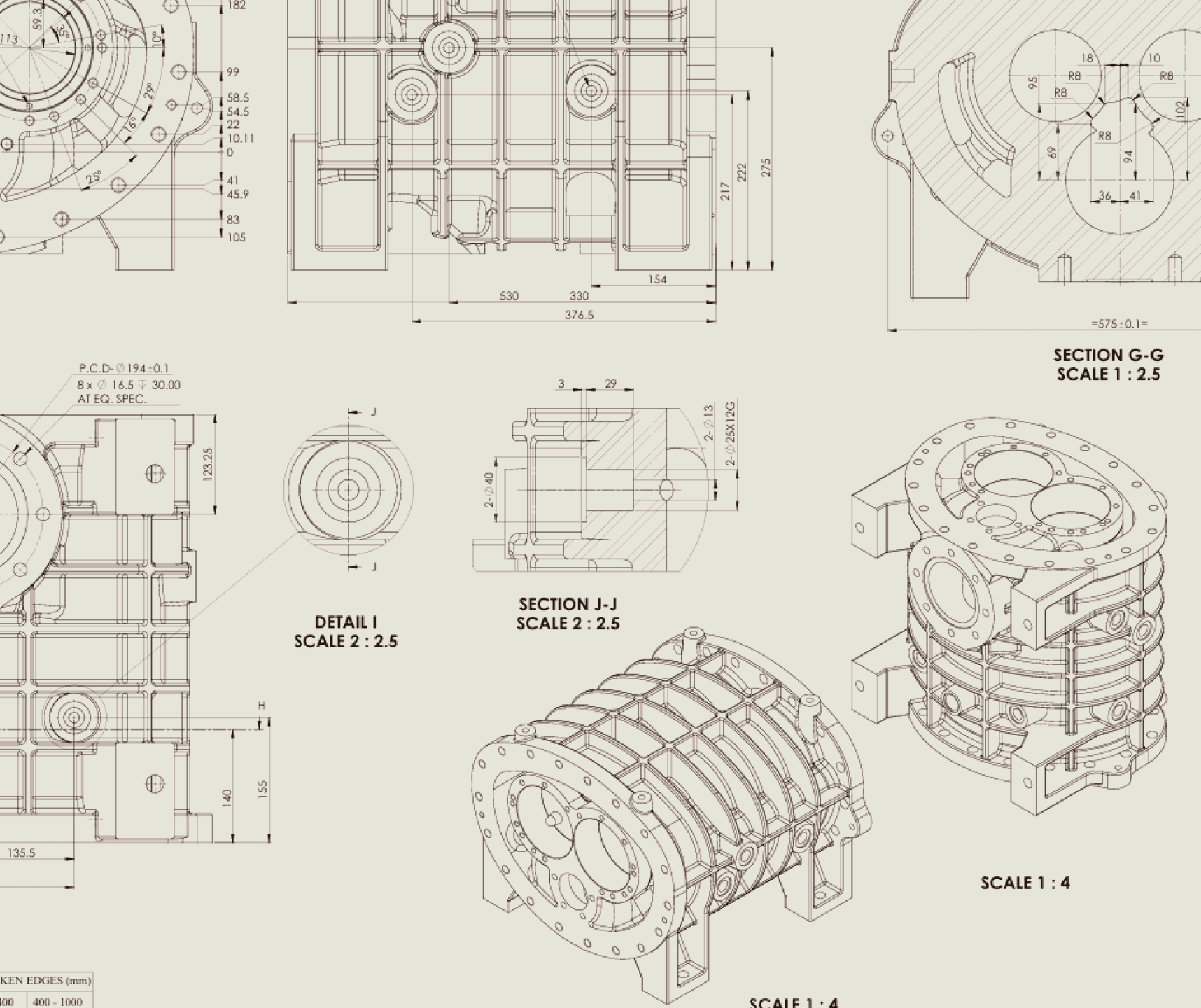

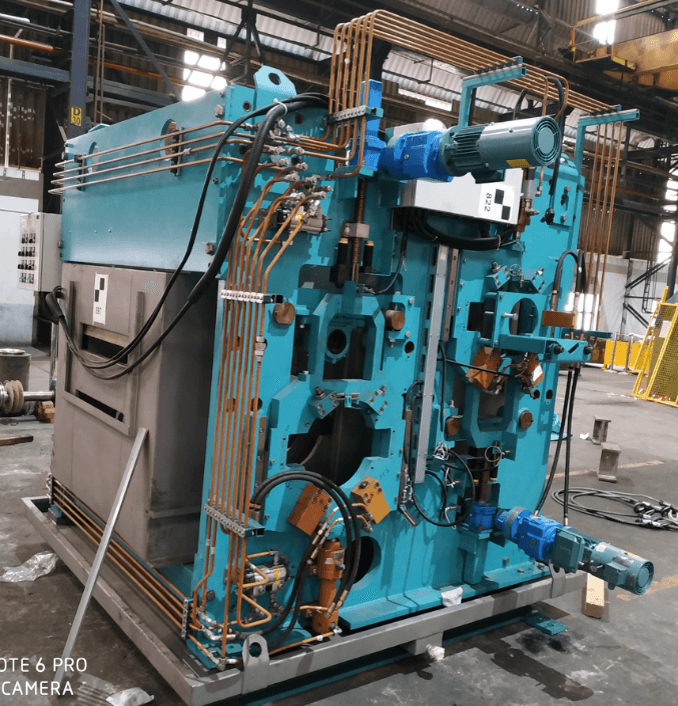

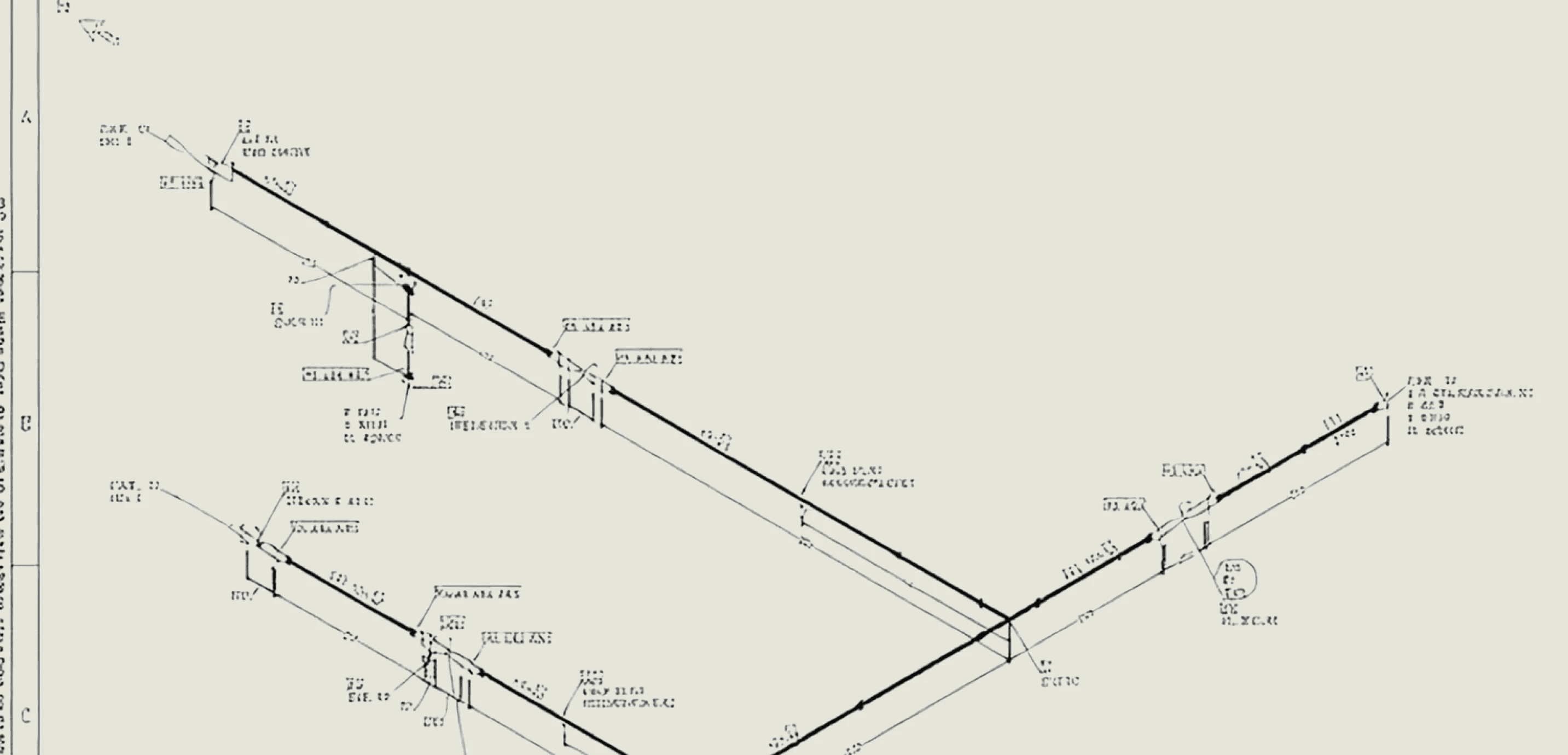

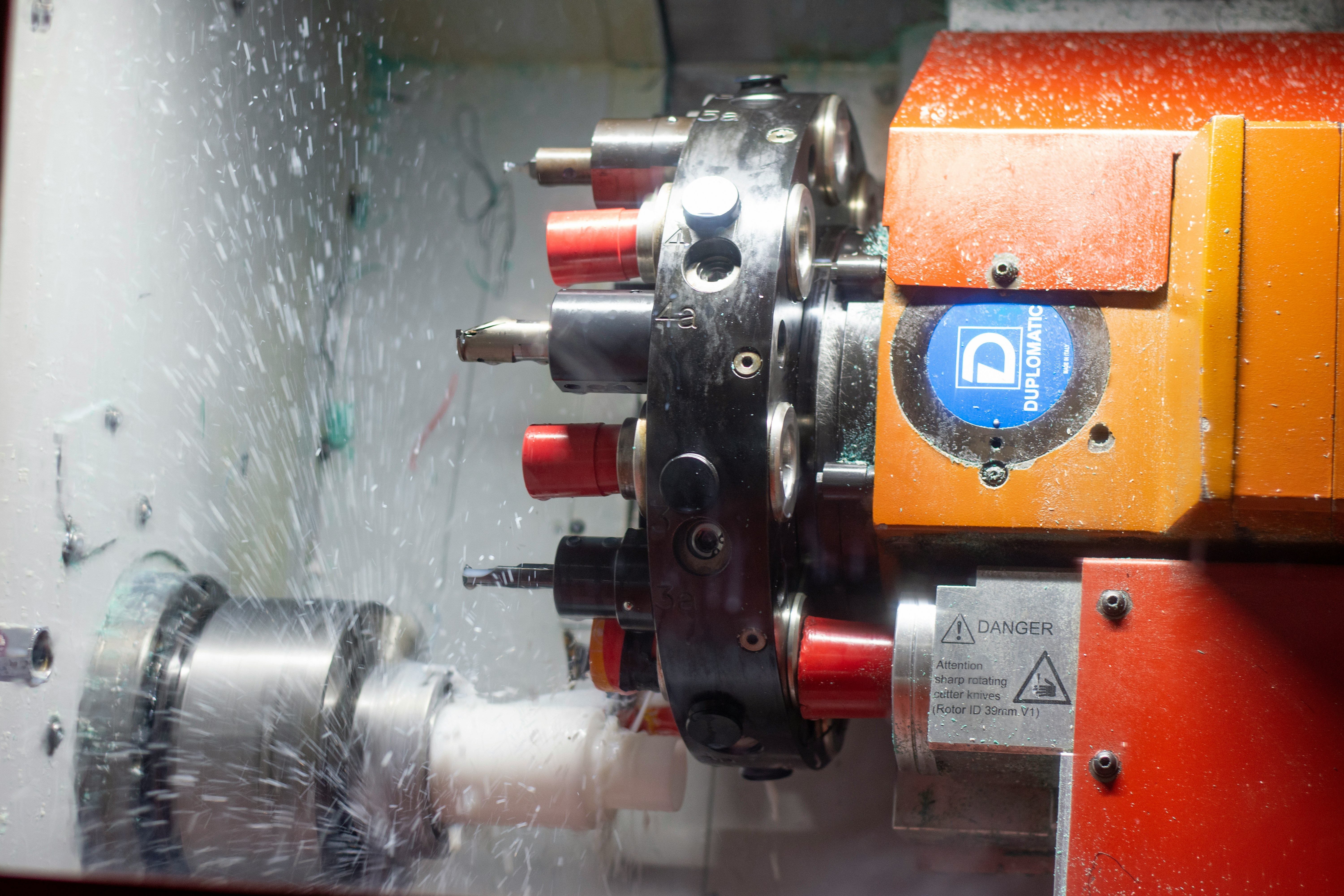

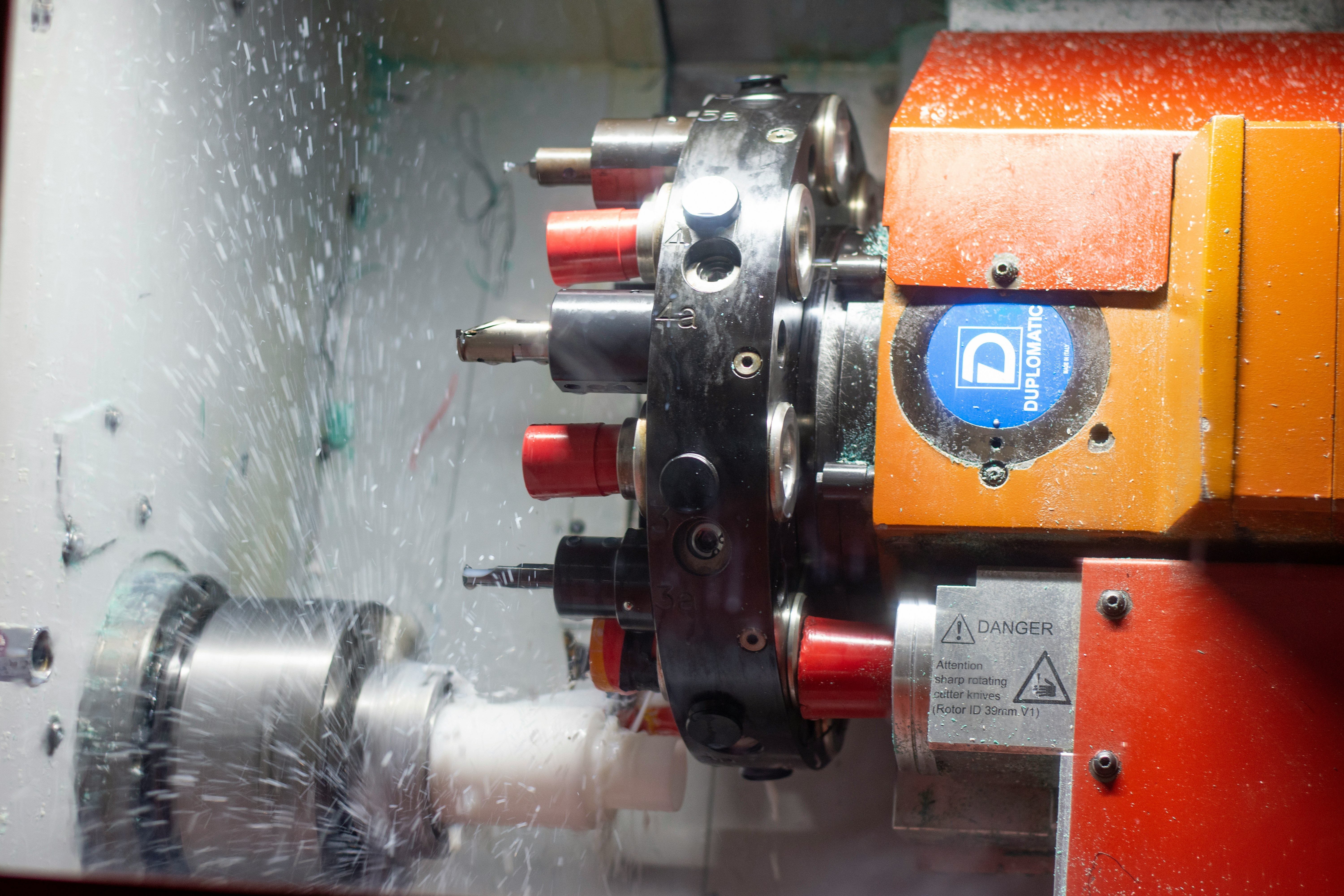

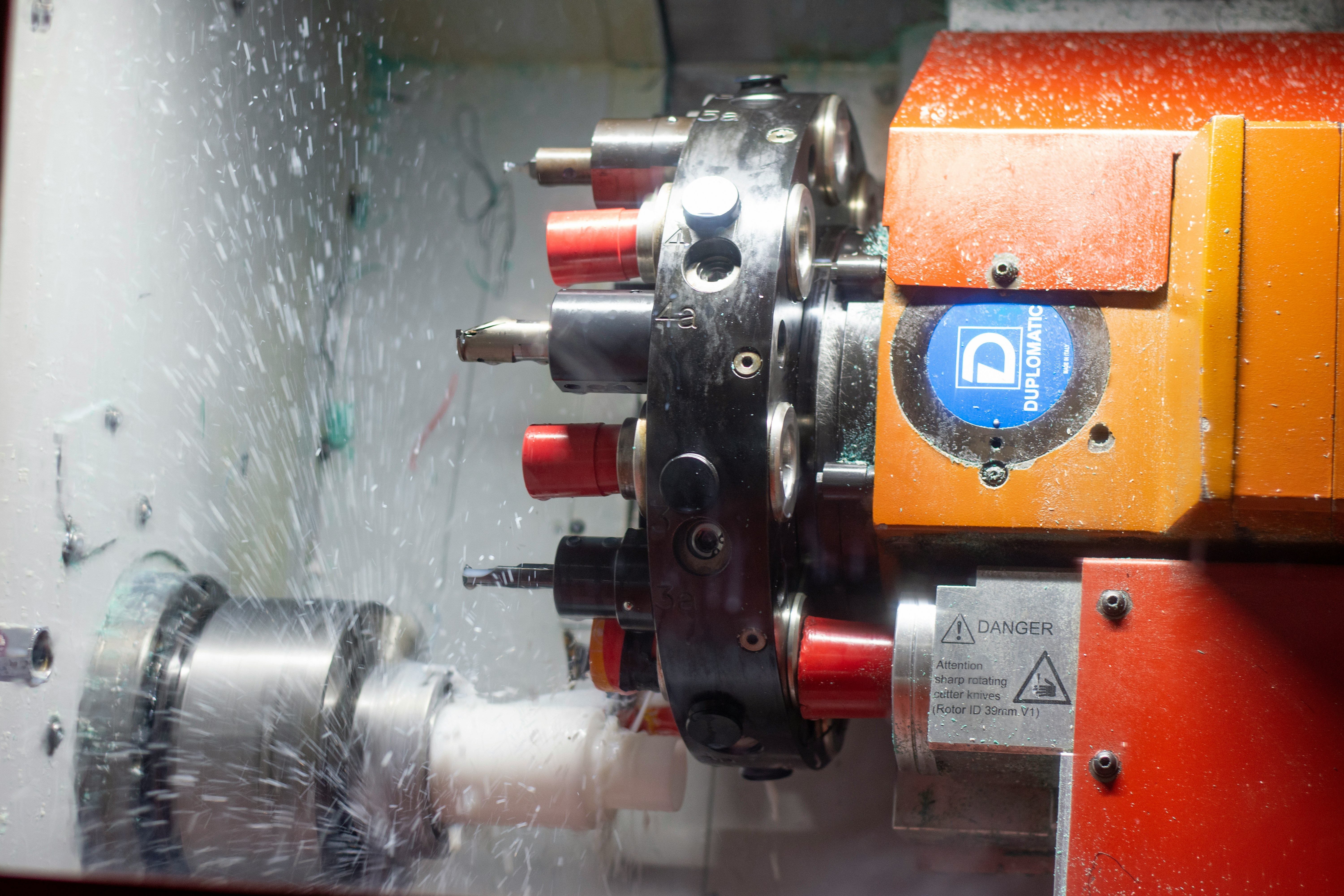

Dimension Engineering for Safety-Critical Installations

SixD offers precision alignment and dimensional verification for equipment, piping interfaces, structures, and skids to ensure fit-up accuracy and safe operation in pressure- and corrosion-sensitive environments.

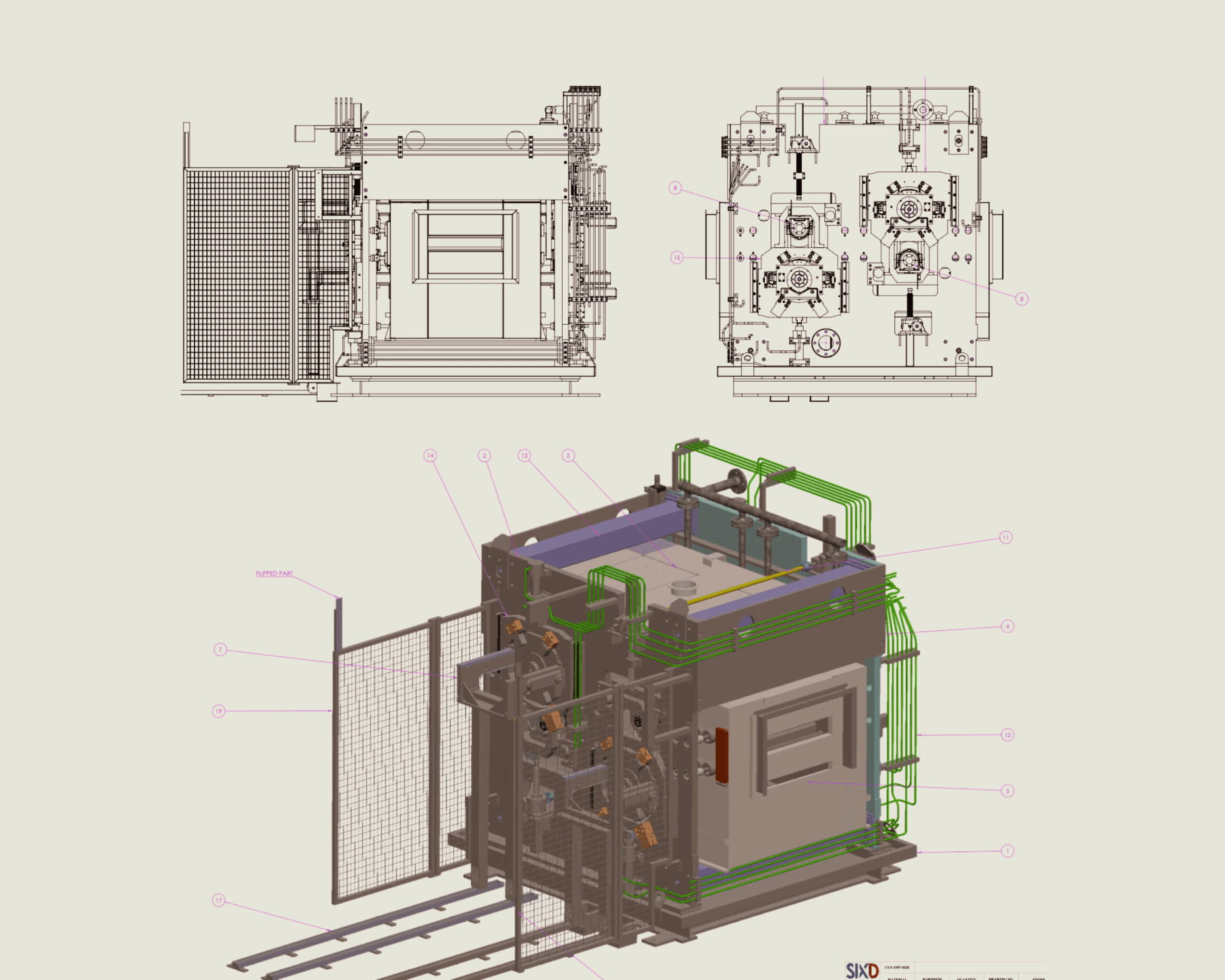

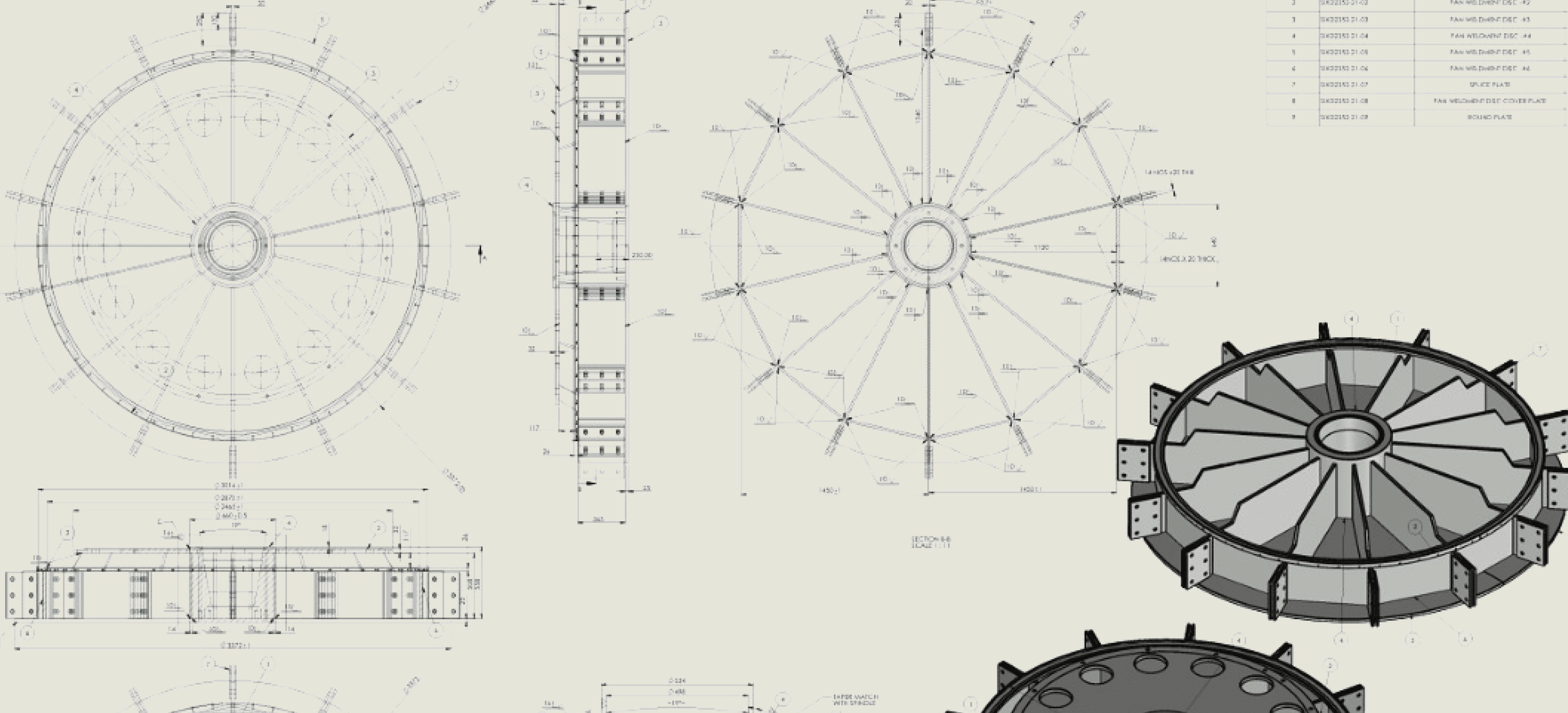

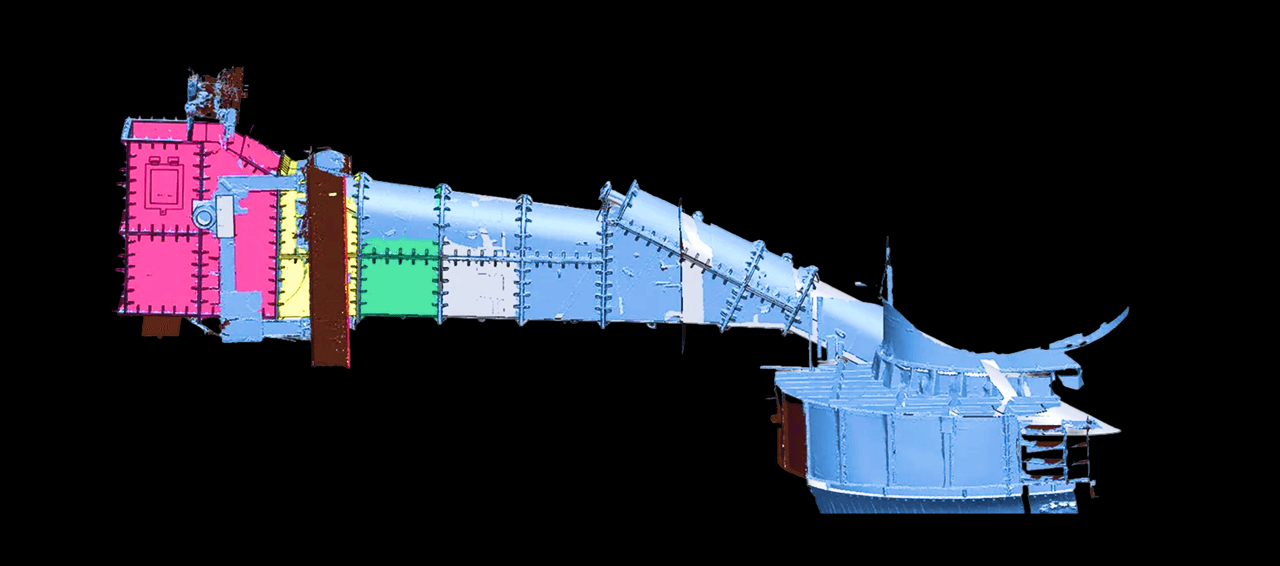

Reverse Engineering & Critical Spares Support

We provide reverse engineering, GA and detailed drawings, and manufacturing-ready documentation for worn, obsolete, or long-lead critical components to support maintenance continuity and operational reliability.

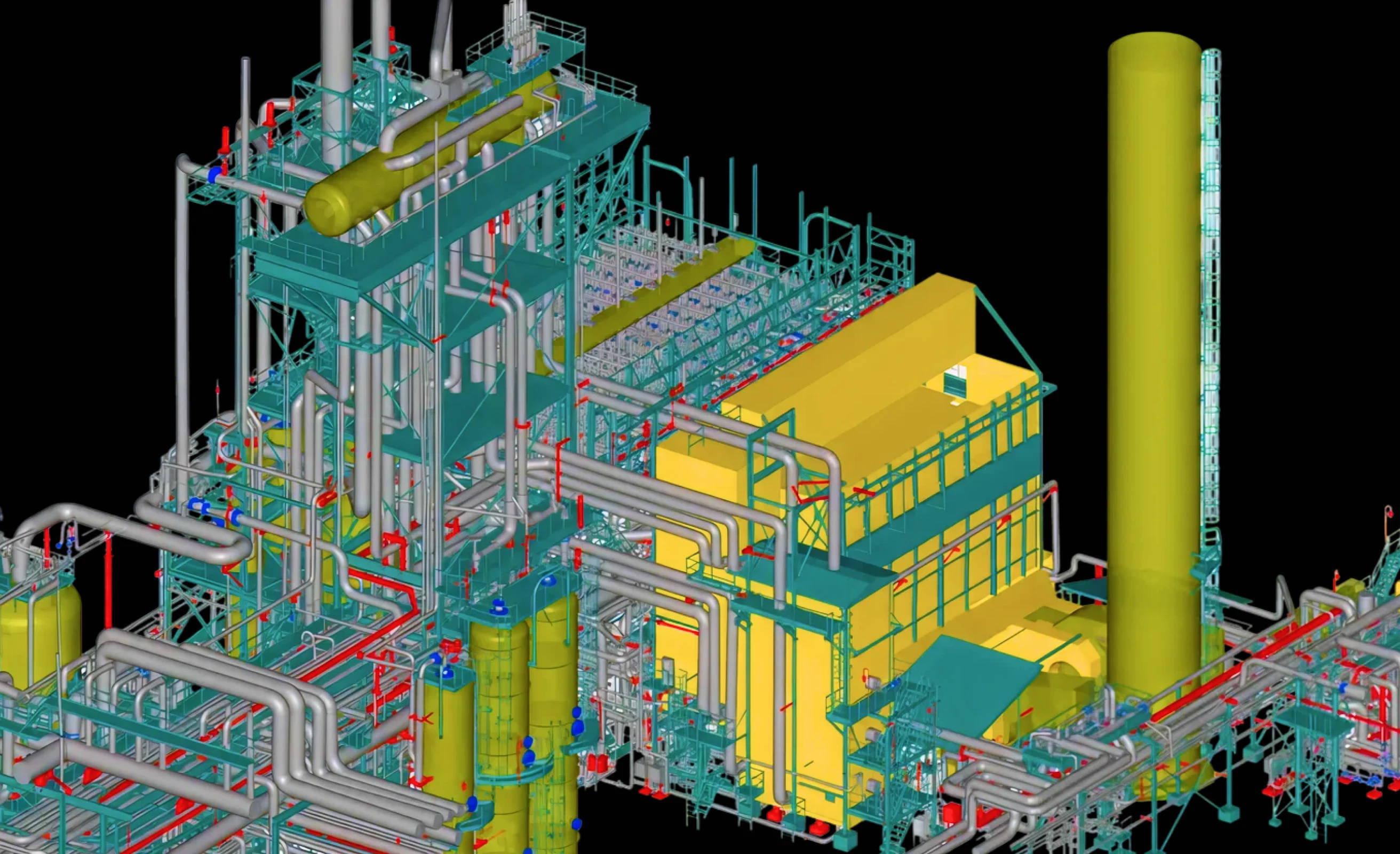

Digital Transformation & Industry 5.0 Enablement

SixD transforms chemical and process plants into digital-ready assets using intelligent documentation, digital twins, and lifecycle data to enable smart maintenance, predictive insights, regulatory traceability, and sustainability initiatives.

(05)

Value Delivered

to Chemicals & Process Sector

SixD delivers engineering precision, industry experience, and digital intelligence to metals and manufacturing, supporting productivity today and enabling more resilient plants for the future.

EPC Assurance

Verified EPC compliance and structured governance strengthen quality control and delivery confidence.

Higher Uptime

Improved reliability and execution certainty support stable operations and predictable project outcomes.

Lower Process Risk

Engineering validation reduces process risk, safety incidents, and compliance gaps across critical operations.

Auditable Records

Accurate, traceable digital engineering documentation supports audits, compliance, and lifecycle decisions.

Faster Revamps

Revamps, retrofits, and expansions are executed faster with verified data and coordinated planning.

Critical Spares

Reliable redesign and supply support for critical spares reduce dependency and operational risk.

(07)

Connect with us

India

Six D Engineering Solutions Pvt Ltd

A-167, Ground Floor, Sector - 63, Noida, Uttar Pradesh, 201 301, INDIA

Middle East

Six D Engineering Solutions FZC

B 49-130, Sharjah Research Technology & Innovation Park (SRTIP), Sharjah, United Arab Emirates

Take the Next Step Toward Engineering Excellence.

From 3D scanning to ongoing asset management - We deliver end-to-end solutions that reduce costs and improve operational efficiency

Contact Us

+91 84481 79046

+971 58556 6837

info@sixdengineering.com

Connect

01

Services

© 2026 SixD Engineering. All rights reserved

Chemicals & Process

(01)

Safety, compliance, and operational reliability are essential in chemicals, specialty chemicals, fertilizers, and process plants. SixD provides engineering-led digital solutions such as as-built digitization, owner’s engineering, dimension engineering, reverse engineering, EPC design validation, and digital twin enablement to ensure accurate execution and lifecycle integrity in safety-critical environments.

(02)

(02)

Engineered Asset Control

Chemical and process plants face high pressure, corrosive environments, strict regulations, and continuous production demands. Undocumented modifications, outdated drawings, or dimensional deviations can cause safety incidents, compliance violations, production losses, and unplanned shutdowns.

To stay competitive and compliant, the chemicals and process industry must use verified engineering data, independent technical oversight, and intelligent digital systems rather than assumptions.

SixD leverages process-industry engineering expertise and advanced digitization technologies to deliver reliable, consistent results for greenfield, brownfield, and retrofit projects.

(02)

Resolving Critical Bottlenecks Across

Resolving Critical Bottlenecks Across

1

Chemicals

Outdated drawings, undocumented modifications, and compliance gaps increase safety and operational risks. SixD provides engineering-grade as-built digitization, owner’s engineering, and digital twins to ensure safe execution, regulatory compliance, and digitally traceable chemical plant operations.

2

Specialty Chemicals

Tight tolerances, frequent changeovers, and inconsistent data limit process efficiency. SixD uses precision dimension engineering, high-accuracy measurement, and digital asset intelligence to enable reliable scale-up, consistent quality, and future-ready specialty chemical manufacturing.

3

Fertilizers

Corrosive environments, alignment drift, and aging assets decrease plant availability. SixD offers precision alignment, reverse engineering, and lifecycle-ready as-built documentation to improve uptime, extend equipment life, and support sustainable fertilizer production.

4

Process Plants

Complex piping, interface mismatches, and constructability risks cause project and revamp delays. Provides FEED–EPC validation, constructability reviews, digital as-built models, and digital twins to ensure predictable execution and Industry 5.0-ready process facilities.

(03)

Trusted by Innovators Industry Leaders

(03)

Trusted by Innovators Industry Leaders

(04)

How SixD Adds Value to Chemicals & Process Assets

As-Built Engineering & Process Plant Digitization

SixD provides high-accuracy 3D laser scanning and intelligent as-built models for reactors, piping networks, storage systems, utilities, and balance-of-plant, creating a single source of truth for engineering, safety reviews, and future modifications.

Independent Technical Oversight

As an independent Owner’s Engineer, SixD safeguards design intent, validates EPC deliverables, and ensures compliance with codes, standards, and safety requirements throughout FEED, EPC, construction, and commissioning phases.

FEED–EPC Design Validation & Constructability Assurance

We validate FEED and EPC designs against actual site conditions, identifying constructability gaps, interface mismatches, and safety risks early to reduce rework, delays, and execution uncertainty.

Dimension Engineering for Safety-Critical Installations

SixD offers precision alignment and dimensional verification for equipment, piping interfaces, structures, and skids to ensure fit-up accuracy and safe operation in pressure- and corrosion-sensitive environments.

Reverse Engineering & Critical Spares Support

We provide reverse engineering, GA and detailed drawings, and manufacturing-ready documentation for worn, obsolete, or long-lead critical components to support maintenance continuity and operational reliability.

Digital Transformation & Industry 5.0 Enablement

SixD transforms chemical and process plants into digital-ready assets using intelligent documentation, digital twins, and lifecycle data to enable smart maintenance, predictive insights, regulatory traceability, and sustainability initiatives.

(05)

Value Delivered

to Chemicals & Process Sector

SixD delivers engineering precision, industry experience, and digital intelligence to metals and manufacturing, supporting productivity today and enabling more resilient plants for the future.

EPC Assurance

Verified EPC compliance and structured governance strengthen quality control and delivery confidence.

Higher Uptime

Improved reliability and execution certainty support stable operations and predictable project outcomes.

Lower Process Risk

Engineering validation reduces process risk, safety incidents, and compliance gaps across critical operations.

Auditable Records

Accurate, traceable digital engineering documentation supports audits, compliance, and lifecycle decisions.

Faster Revamps

Revamps, retrofits, and expansions are executed faster with verified data and coordinated planning.

Critical Spares

Reliable redesign and supply support for critical spares reduce dependency and operational risk.

(07)

Connect with us

India

Six D Engineering Solutions Pvt Ltd

A-167, Ground Floor, Sector - 63, Noida, Uttar Pradesh, 201 301, INDIA

Middle East

Six D Engineering Solutions FZC

B 49-130, Sharjah Research Technology & Innovation Park (SRTIP), Sharjah, United Arab Emirates

Take the Next Step Toward Engineering Excellence.

From 3D scanning to ongoing asset management - We deliver end-to-end solutions that reduce costs and improve operational efficiency

01

Services

Contact Us

+91 84481 79046

+971 58556 6837

info@sixdengineering.com

Connect

© 2026 SixD Engineering. All rights reserved

Chemicals & Process

(01)

Safety, compliance, and operational reliability are essential in chemicals, specialty chemicals, fertilizers, and process plants. SixD provides engineering-led digital solutions such as as-built digitization, owner’s engineering, dimension engineering, reverse engineering, EPC design validation, and digital twin enablement to ensure accurate execution and lifecycle integrity in safety-critical environments.

(02)

(02)

Engineered Asset Control

Chemical and process plants face high pressure, corrosive environments, strict regulations, and continuous production demands. Undocumented modifications, outdated drawings, or dimensional deviations can cause safety incidents, compliance violations, production losses, and unplanned shutdowns.

To stay competitive and compliant, the chemicals and process industry must use verified engineering data, independent technical oversight, and intelligent digital systems rather than assumptions.

SixD leverages process-industry engineering expertise and advanced digitization technologies to deliver reliable, consistent results for greenfield, brownfield, and retrofit projects.

(02)

Resolving Critical Bottlenecks Across

Resolving Critical Bottlenecks Across

1

Chemicals

Outdated drawings, undocumented modifications, and compliance gaps increase safety and operational risks. SixD provides engineering-grade as-built digitization, owner’s engineering, and digital twins to ensure safe execution, regulatory compliance, and digitally traceable chemical plant operations.

2

Specialty Chemicals

Tight tolerances, frequent changeovers, and inconsistent data limit process efficiency. SixD uses precision dimension engineering, high-accuracy measurement, and digital asset intelligence to enable reliable scale-up, consistent quality, and future-ready specialty chemical manufacturing.

3

Fertilizers

Corrosive environments, alignment drift, and aging assets decrease plant availability. SixD offers precision alignment, reverse engineering, and lifecycle-ready as-built documentation to improve uptime, extend equipment life, and support sustainable fertilizer production.

4

Process Plants

Complex piping, interface mismatches, and constructability risks cause project and revamp delays. Provides FEED–EPC validation, constructability reviews, digital as-built models, and digital twins to ensure predictable execution and Industry 5.0-ready process facilities.

(03)

Trusted by Innovators Industry Leaders

(03)

Trusted by Innovators Industry Leaders

(04)

How SixD Adds Value to Chemicals & Process Assets

As-Built Engineering & Process Plant Digitization

SixD provides high-accuracy 3D laser scanning and intelligent as-built models for reactors, piping networks, storage systems, utilities, and balance-of-plant, creating a single source of truth for engineering, safety reviews, and future modifications.

Independent Technical Oversight

As an independent Owner’s Engineer, SixD safeguards design intent, validates EPC deliverables, and ensures compliance with codes, standards, and safety requirements throughout FEED, EPC, construction, and commissioning phases.

FEED–EPC Design Validation & Constructability Assurance

We validate FEED and EPC designs against actual site conditions, identifying constructability gaps, interface mismatches, and safety risks early to reduce rework, delays, and execution uncertainty.

Dimension Engineering for Safety-Critical Installations

SixD offers precision alignment and dimensional verification for equipment, piping interfaces, structures, and skids to ensure fit-up accuracy and safe operation in pressure- and corrosion-sensitive environments.

Reverse Engineering & Critical Spares Support

We provide reverse engineering, GA and detailed drawings, and manufacturing-ready documentation for worn, obsolete, or long-lead critical components to support maintenance continuity and operational reliability.

Digital Transformation & Industry 5.0 Enablement

SixD transforms chemical and process plants into digital-ready assets using intelligent documentation, digital twins, and lifecycle data to enable smart maintenance, predictive insights, regulatory traceability, and sustainability initiatives.

(05)

Value Delivered

to Chemicals & Process Sector

SixD delivers engineering precision, industry experience, and digital intelligence to metals and manufacturing, supporting productivity today and enabling more resilient plants for the future.

EPC Assurance

Verified EPC compliance and structured governance strengthen quality control and delivery confidence.

Higher Uptime

Improved reliability and execution certainty support stable operations and predictable project outcomes.

Lower Process Risk

Engineering validation reduces process risk, safety incidents, and compliance gaps across critical operations.

Auditable Records

Accurate, traceable digital engineering documentation supports audits, compliance, and lifecycle decisions.

Faster Revamps

Revamps, retrofits, and expansions are executed faster with verified data and coordinated planning.

Critical Spares

Reliable redesign and supply support for critical spares reduce dependency and operational risk.

(07)

Connect with us

India

Six D Engineering Solutions Pvt Ltd

A-167, Ground Floor, Sector - 63, Noida, Uttar Pradesh, 201 301, INDIA

Middle East

Six D Engineering Solutions FZC

B 49-130, Sharjah Research Technology & Innovation Park (SRTIP), Sharjah, United Arab Emirates

Take the Next Step Toward Engineering Excellence.

From 3D scanning to ongoing asset management - We deliver end-to-end solutions that reduce costs and improve operational efficiency

01

Services

Contact Us

+91 84481 79046

+971 58556 6837

info@sixdengineering.com

Connect

© 2026 SixD Engineering. All rights reserved