Dimension Engineering Service

Dimension Engineering Service

(01)

(01)

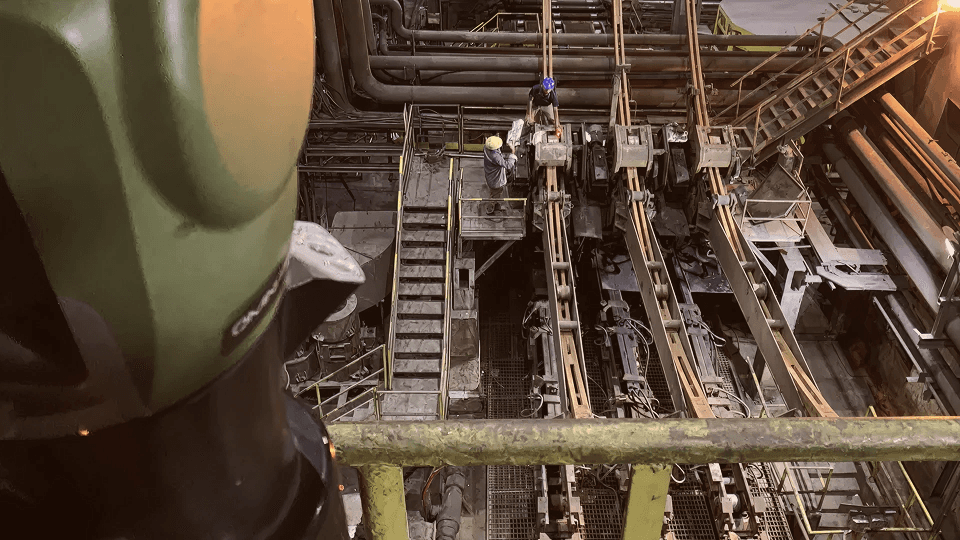

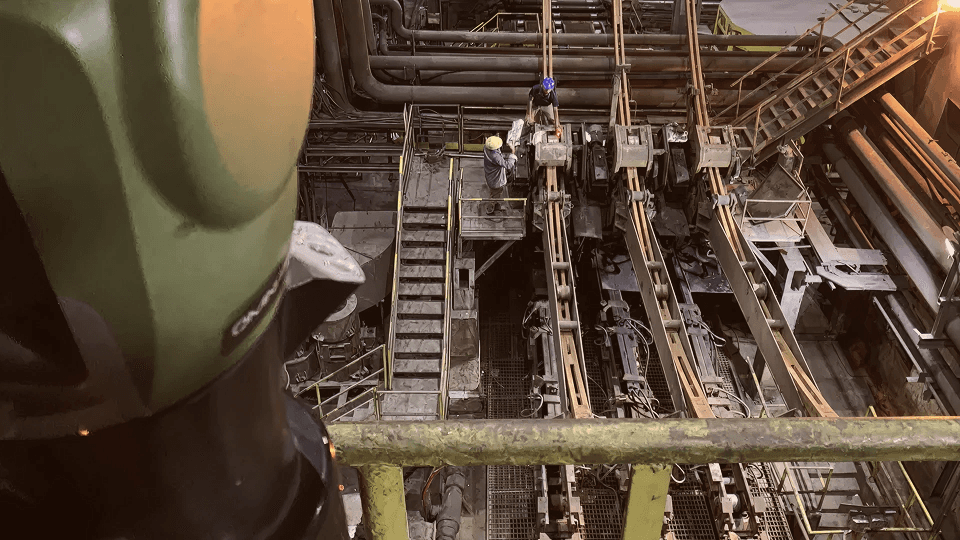

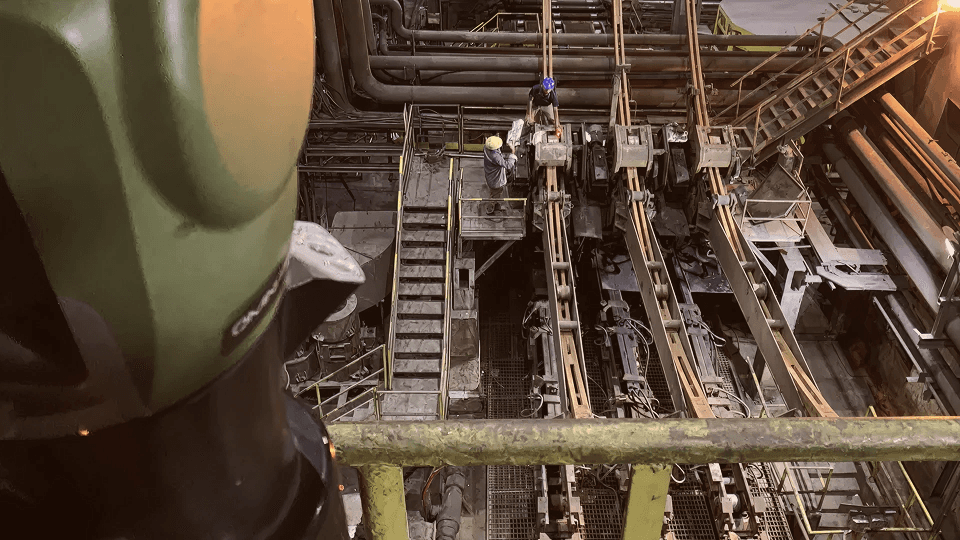

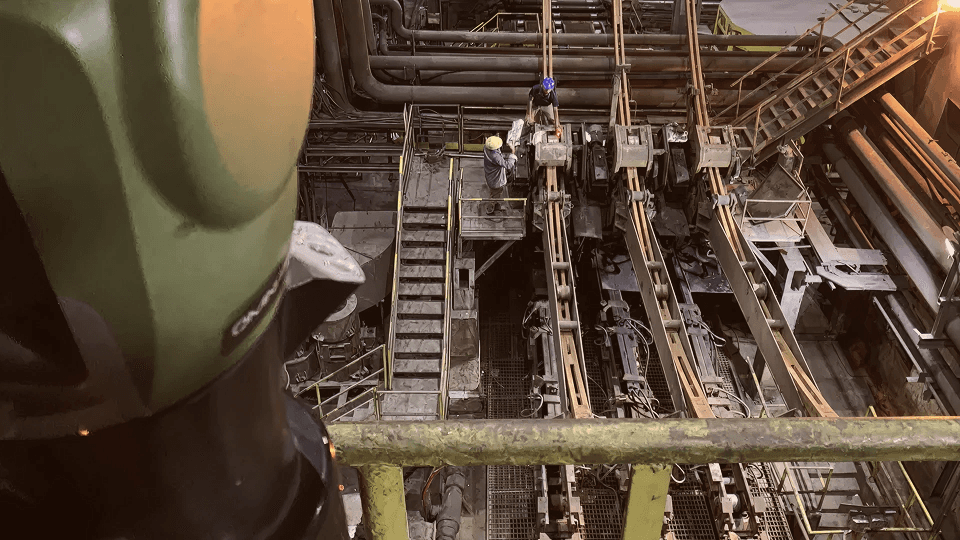

We ensure your projects meet the highest standards of accuracy, geometric integrity, and alignment for critical equipment, structures, and assemblies. Our dimension engineering solutions eliminate fit-up risks during installation, revamps, and shutdown maintenance.

We ensure your projects meet the highest standards of accuracy, geometric integrity, and alignment for critical equipment, structures, and assemblies. Our dimension engineering solutions eliminate fit-up risks during installation, revamps, and shutdown maintenance.

Ensuring precision alignment, geometric integrity, and zero fit-up risk.

Ensuring precision alignment, geometric integrity, and zero fit-up risk.

Ensuring precision alignment, geometric integrity, and zero fit-up risk.

3D metrology is essential for successful industrial execution.

We provide high-accuracy geometric control, alignment engineering, and dimensional verification to ensure critical equipment, structures, and assemblies are installed as designed, without clashes, rework, or delays. Using advanced 3D measurement technologies, laser trackers, and intelligent dimensional analysis, we help EPCs, OEMs, and asset owners eliminate fit-up risks throughout project phases.

Total Clients

0+

Total Clients

0+

Years of experience in Dimension Engineering

0+

Years of experience in Dimension Engineering

0+

Projects Completed

0+

Projects Completed

0+

Industries

Sectors We Serve

(04)

1

Oil & Gas

From upstream production to downstream refining, SixD provides engineering precision, digital asset intelligence, and Industry 5.0–ready oil and gas solutions across Southeast Asia, North America, and global energy markets.

2

Power & Energy

The power industry forms the backbone of modern infrastructure, ensuring homes, industries, and economies run seamlessly. From conventional thermal and hydro plants to emerging renewable energy systems, the sector is undergoing a rapid transformation driven by efficiency & sustainability.

3

Metals & Manufacturing

Operational continuity, precision, and asset reliability are critical in iron and steel, non-ferrous metals, mining and mineral processing, and heavy manufacturing. SixD provides engineering-led digital solutions such as dimension engineering, as-built digitization, reverse engineering, owner’s engineering, and digital twin enablement to enhance accuracy, resilience, and performance in metals and manufacturing assets.

4

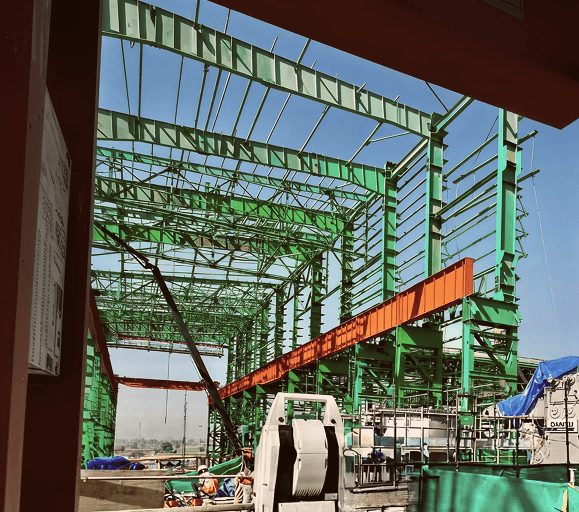

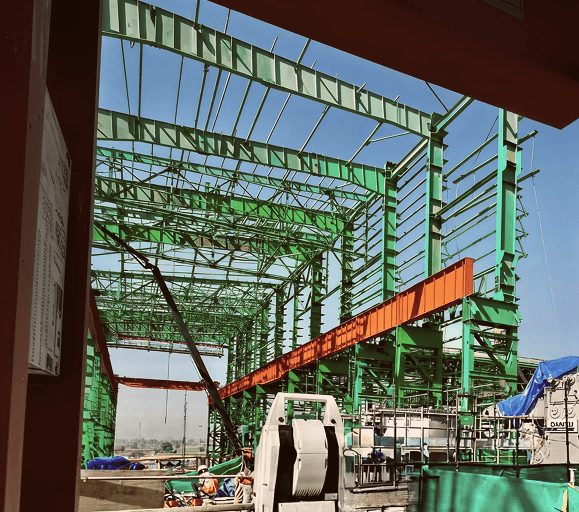

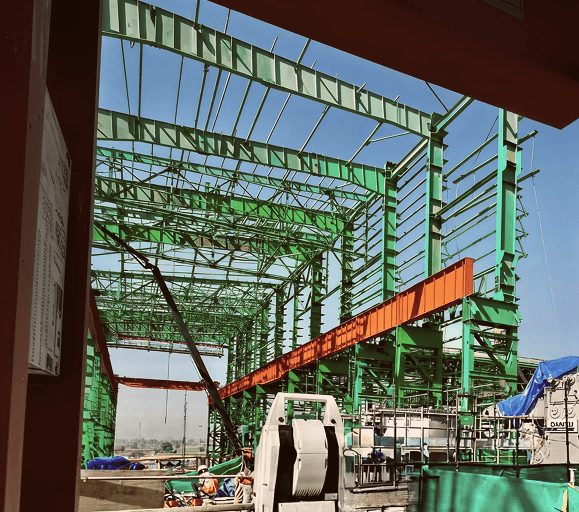

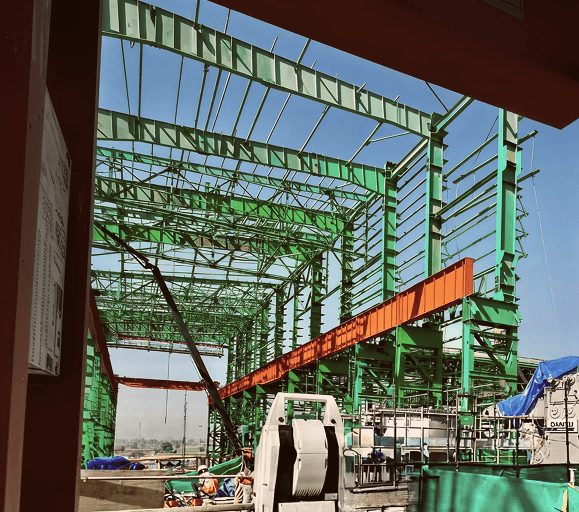

Infrastructure & Built Environment

Precision, coordination, and lifecycle clarity are essential for industrial infrastructure, cement plants, utilities, BIM/MEP developments, and heritage structures. SixD delivers engineering-grade digital solutions, including as-built digitization, BIM integration, dimension engineering, underground digitization, owner’s engineering, and digital twin enablement, to ensure accurate execution and long-term asset reliability.

5

Transportation, Marine & Defence

Precision, compliance, and operational reliability are essential across Automotive & EV, Aerospace, Defence & Naval, Marine & Offshore, and Railways & Metro sectors. SixD provides engineering-led digital solutions such as high-precision 3D measurement and inspection, dimension engineering, reverse engineering, as-built digitization, owner’s engineering, and digital twin enablement to ensure accuracy, safety, and lifecycle integrity.

Trusted Across Every Project Phase

Installation & Erection

Installation & Erection services ensure that every component is positioned, aligned, and assembled with absolute dimensional accuracy.

Revamp

Shutdown Maintenance

Design Validation

Power

The power industry forms the backbone of modern infrastructure, ensuring homes, industries, and economies run seamlessly. From conventional thermal and hydro plants to emerging renewable energy systems, the sector is undergoing a rapid transformation driven by efficiency, sustainability, and digital adoption.

Power & Energy

Precision, reliability, and lifecycle efficiency are critical in Thermal, Combined Cycle, Hydro and Pump Storage, Nuclear, Renewable Energy, and Energy Storage plants. SixD provides engineering-led digital solutions such as as-built digitization, dimension engineering, owner’s engineering, reverse engineering, Digital Profile Mapping (DPM), and digital twin enablement to support safe execution, optimal performance, and long-term asset integrity.

Metals

The metal industry is the backbone of infrastructure, construction, automotive, energy, and countless other sectors worldwide. As one of the most resource-intensive industries, it faces constant pressure to improve efficiency, reduce downtime, and comply with strict environmental and safety standards.

Metals & Manufacturing

Operational continuity, precision, and asset reliability are critical in iron and steel, non-ferrous metals, mining and mineral processing, and heavy manufacturing. SixD provides engineering-led digital solutions such as dimension engineering, as-built digitization, reverse engineering, owner’s engineering, and digital twin enablement to enhance accuracy, resilience, and performance in metals and manufacturing assets.

Transportation

The transportation industry thrives on efficiency, safety, and seamless movement — and SixD helps keep it all in motion. We provide precision 3D scanning, reverse engineering, and dimensional validation for rail networks, metro systems, heavy vehicles, and logistics infrastructure.

Green Energy & Sustainability

Precision engineering and digital intelligence are critical for green hydrogen, renewable energy integration, decarbonization, and Industry 5.0 programs. SixD provides engineering-led digital solutions such as as-built digitization, dimension engineering, owner’s engineering, reverse engineering, digital twins, and lifecycle data integration to support safe, efficient, and sustainable energy transitions.

Transportation, Marine & Defence

Precision, compliance, and operational reliability are essential across Automotive & EV, Aerospace, Defence & Naval, Marine & Offshore, and Railways & Metro sectors. SixD provides engineering-led digital solutions such as high-precision 3D measurement and inspection, dimension engineering, reverse engineering, as-built digitization, owner’s engineering, and digital twin enablement to ensure accuracy, safety, and lifecycle integrity.

Oil & Gas

From upstream production to downstream refining, SixD provides engineering precision, digital asset intelligence, and Industry 5.0–ready oil and gas solutions across Southeast Asia, North America, and global energy markets.

Infrastructure & Built Environment

Precision, coordination, and lifecycle clarity are essential for industrial infrastructure, cement plants, utilities, BIM/MEP developments, and heritage structures. SixD delivers engineering-grade digital solutions, including as-built digitization, BIM integration, dimension engineering, underground digitization, owner’s engineering, and digital twin enablement, to ensure accurate execution and long-term asset reliability.

Power & Energy

Precision, reliability, and lifecycle efficiency are critical in Thermal, Combined Cycle, Hydro and Pump Storage, Nuclear, Renewable Energy, and Energy Storage plants. SixD provides engineering-led digital solutions such as as-built digitization, dimension engineering, owner’s engineering, reverse engineering, Digital Profile Mapping (DPM), and digital twin enablement to support safe execution, optimal performance, and long-term asset integrity.

Metals & Manufacturing

Operational continuity, precision, and asset reliability are critical in iron and steel, non-ferrous metals, mining and mineral processing, and heavy manufacturing. SixD provides engineering-led digital solutions such as dimension engineering, as-built digitization, reverse engineering, owner’s engineering, and digital twin enablement to enhance accuracy, resilience, and performance in metals and manufacturing assets.

Green Energy & Sustainability

Precision engineering and digital intelligence are critical for green hydrogen, renewable energy integration, decarbonization, and Industry 5.0 programs. SixD provides engineering-led digital solutions such as as-built digitization, dimension engineering, owner’s engineering, reverse engineering, digital twins, and lifecycle data integration to support safe, efficient, and sustainable energy transitions.

Transportation, Marine & Defence

Precision, compliance, and operational reliability are essential across Automotive & EV, Aerospace, Defence & Naval, Marine & Offshore, and Railways & Metro sectors. SixD provides engineering-led digital solutions such as high-precision 3D measurement and inspection, dimension engineering, reverse engineering, as-built digitization, owner’s engineering, and digital twin enablement to ensure accuracy, safety, and lifecycle integrity.

Oil & Gas

From upstream production to downstream refining, SixD provides engineering precision, digital asset intelligence, and Industry 5.0–ready oil and gas solutions across Southeast Asia, North America, and global energy markets.

Infrastructure & Built Environment

Precision, coordination, and lifecycle clarity are essential for industrial infrastructure, cement plants, utilities, BIM/MEP developments, and heritage structures. SixD delivers engineering-grade digital solutions, including as-built digitization, BIM integration, dimension engineering, underground digitization, owner’s engineering, and digital twin enablement, to ensure accurate execution and long-term asset reliability.

(06)

Core Strength

Geometrical Parameters & Condition Assessment

We provide precision verification and correction of equipment, structures, skids, piping interfaces, and rotating machinery to meet design and OEM tolerances.

Provides accurate inspection of geometrical parameters such as flatness, verticality, concentricity, and cylindricity

Enables early detection of wear, misalignment, or deviations

Prevents minor issues from escalating into costly failures

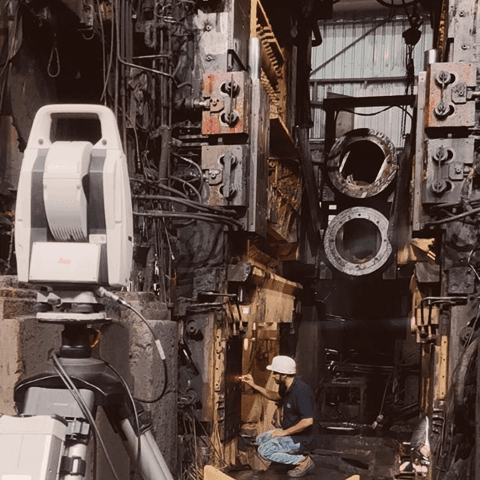

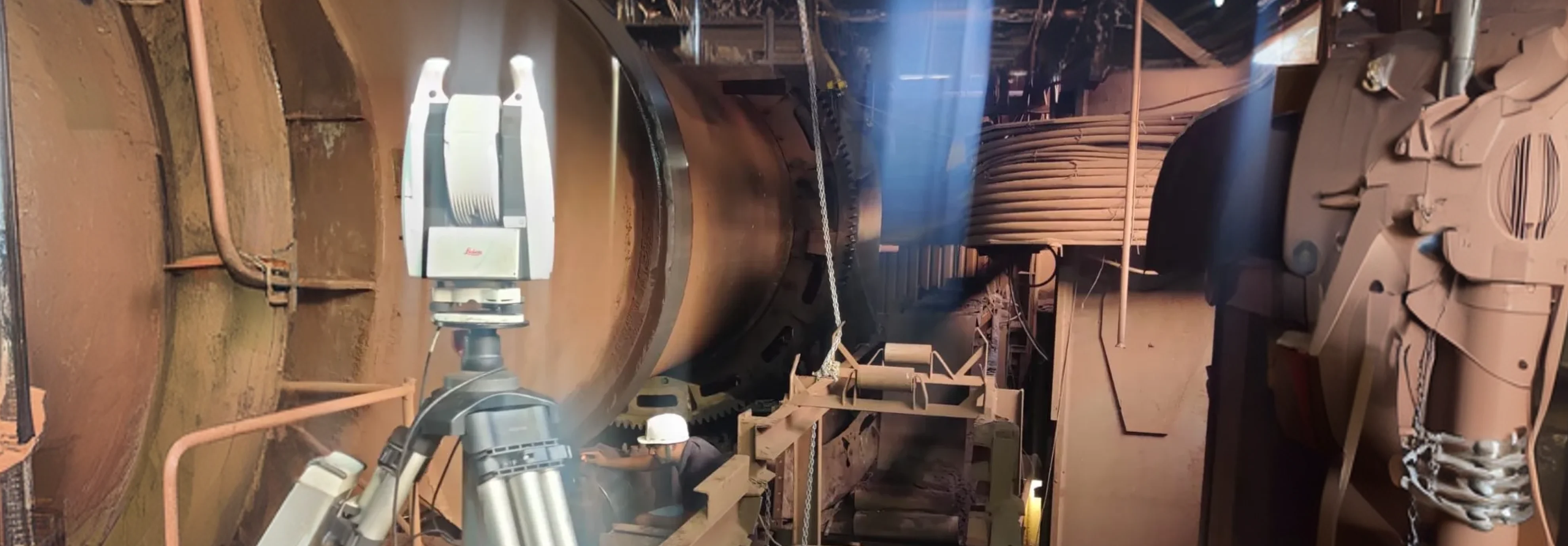

3D Measurement for Installation Assistance

We conduct pre- and post-installation dimensional checks to ensure first-time-right assembly, reducing site rework and project delays.

Uses laser-based 3D metrology to guide equipment and machinery installation

Ensures accurate fit-up during installation.

Reduces rework and installation errors

Speeds up the commissioning process

Brownfield Reference Capture & Benchmarking

We validate dimensions of existing assets before modification, expansion, or retrofitting to ensure seamless integration with new equipment.

Captures and preserves existing reference points

Installs new, robust benchmarks tied to absolute coordinates

Ensures consistency and reliability for all future measurements

Alignment & Installation of Critical Components

We conduct high-quality dimensional inspections during shutdowns to support maintenance, replacement, and realignment within tight outage windows.

Implements streamlined dimensional control for critical alignments during erection.

Provides real-time guidance throughout the installation process

Reduces crane time and minimizes shutdown duration

Ensures precise and accurate installation

Design Validation

We perform dimensional verification during Front End Engineering Design (FEED) and EPC stages to confirm constructability and prevent downstream clashes.

Validation of design intent, interfaces, and tolerances to ensure constructible, clash-free layouts

Early identification of dimensional conflicts and clearance issues before execution

Integration of as-is dimensional data for accurate brownfield FEED and EPC planning

Reduction of site rework, delays, and cost overruns through proactive dimensional checks

Improved FEED maturity and EPC execution readiness with data-driven verification

(07)

Why Choose SixD

for Dimension Engineering?

Proven Domain Expertise

Decades of experience across power, oil & gas, metals, and heavy industries, with execution insight across FEED, EPC, commissioning, and brownfield projects.

OEM & Standards Compliance

All dimensional activities follow OEM tolerances and international standards, ensuring design intent from engineering through operation.

Flexible On-Site Execution

Portable precision systems enable accurate measurements in live plants and shutdowns with minimal operational disruption.

High-Precision Accuracy

Advanced metrology delivers accurate, auditable dimensional data for large-scale and critical assets.

End-to-End Control

Complete support from benchmarking and design validation to alignment and final acceptance.

Lifecycle Value

Reduced rework, downtime, and lifecycle cost, supported by future-ready digital dimensional data.

Trusted Across Every Project Phase

Trusted Across Every Project Phase

Trusted Across Every Project Phase

Installation & Erection

Installation & Erection services ensure that every component is positioned, aligned, and assembled with absolute dimensional accuracy.

Revamp

Shutdown Maintenance

Design Validation

Installation & Erection

Installation & Erection services ensure that every component is positioned, aligned, and assembled with absolute dimensional accuracy.

Revamp

Shutdown Maintenance

Design Validation

Installation & Erection

Installation & Erection services ensure that every component is positioned, aligned, and assembled with absolute dimensional accuracy.

Revamp

Shutdown Maintenance

Design Validation

(07)

Why Choose SixD for Dimension Engineering?

Why Choose SixD for Dimension Engineering?

Why Choose SixD for Dimension Engineering?

Proven Domain Expertise

Decades of experience across power, oil & gas, metals, and heavy industries, with execution insight across FEED, EPC, commissioning, and brownfield projects.

Proven Domain Expertise

Decades of experience across power, oil & gas, metals, and heavy industries, with execution insight across FEED, EPC, commissioning, and brownfield projects.

OEM & Standards Compliance

All dimensional activities follow OEM tolerances and international standards, ensuring design intent from engineering through operation.

OEM & Standards Compliance

All dimensional activities follow OEM tolerances and international standards, ensuring design intent from engineering through operation.

OEM & Standards Compliance

All dimensional activities follow OEM tolerances and international standards, ensuring design intent from engineering through operation.

Flexible On-Site Execution

Portable precision systems enable accurate measurements in live plants and shutdowns with minimal operational disruption.

Flexible On-Site Execution

Portable precision systems enable accurate measurements in live plants and shutdowns with minimal operational disruption.

High-Precision Accuracy

Advanced metrology delivers accurate, auditable dimensional data for large-scale and critical assets.

High-Precision Accuracy

Advanced metrology delivers accurate, auditable dimensional data for large-scale and critical assets.

End-to-End Control

Complete support from benchmarking and design validation to alignment and final acceptance.

End-to-End Control

Complete support from benchmarking and design validation to alignment and final acceptance.

End-to-End Control

Complete support from benchmarking and design validation to alignment and final acceptance.

Lifecycle Value

Reduced rework, downtime, and lifecycle cost, supported by future-ready digital dimensional data.

Lifecycle Value

Reduced rework, downtime, and lifecycle cost, supported by future-ready digital dimensional data.

(09)

Connect with us

India

Six D Engineering Solutions Pvt Ltd

A-167, Ground Floor, Sector - 63, Noida, Uttar Pradesh, 201 301, INDIA

Middle East

Six D Engineering Solutions FZC

B 49-130, Sharjah Research Technology & Innovation Park (SRTIP), Sharjah, United Arab Emirates

(09)

Connect with us

India

Six D Engineering Solutions Pvt Ltd

A-167, Ground Floor, Sector - 63, Noida, Uttar Pradesh, 201 301, INDIA

Middle East

Six D Engineering Solutions FZC

B 49-130, Sharjah Research Technology & Innovation Park (SRTIP), Sharjah, United Arab Emirates

(09)

Connect with us

India

Six D Engineering Solutions Pvt Ltd

A-167, Ground Floor, Sector - 63, Noida, Uttar Pradesh, 201 301, INDIA

Middle East

Six D Engineering Solutions FZC

B 49-130, Sharjah Research Technology & Innovation Park (SRTIP), Sharjah, United Arab Emirates

Take the Next Step Toward Engineering Excellence.

From 3D scanning to ongoing asset management - We deliver end-to-end solutions that reduce costs and improve operational efficiency

Contact Us

+91 84481 79046

+971 58556 6837

info@sixdengineering.com

Connect

01

Services

© 2026 SixD Engineering. All rights reserved

Take the Next Step Toward Engineering Excellence.

From 3D scanning to ongoing asset management - We deliver end-to-end solutions that reduce costs and improve operational efficiency

01

Services

Contact Us

+91 84481 79046

+971 58556 6837

info@sixdengineering.com

Connect

© 2026 SixD Engineering. All rights reserved

Take the Next Step Toward Engineering Excellence.

From 3D scanning to ongoing asset management - We deliver end-to-end solutions that reduce costs and improve operational efficiency

01

Services

Contact Us

+91 84481 79046

+971 58556 6837

info@sixdengineering.com

Connect

© 2026 SixD Engineering. All rights reserved

Geometrical Parameters & Condition Assessment

• Provides accurate inspection of geometrical parameters such as flatness, verticality, concentricity, and cylindricity

• Enables early detection of wear, misalignment, or deviations

• Prevents minor issues from escalating into costly failures

Provides accurate inspection of geometrical parameters such as flatness, verticality, concentricity, and cylindricity

Geometrical Parameters & Condition Assessment

We provide precision verification and correction of equipment, structures, skids, piping interfaces, and rotating machinery to meet design and OEM tolerances.

Enables early detection of wear, misalignment, or deviations

Prevents minor issues from escalating into costly failures

Provides accurate inspection of geometrical parameters such as flatness, verticality, concentricity, and cylindricity

Geometrical Parameters & Condition Assessment

We provide precision verification and correction of equipment, structures, skids, piping interfaces, and rotating machinery to meet design and OEM tolerances.

Enables early detection of wear, misalignment, or deviations

Prevents minor issues from escalating into costly failures

Provides accurate inspection of geometrical parameters such as flatness, verticality, concentricity, and cylindricity

3D Measurement for Installation Assistance

• Uses laser-based 3D metrology to guide equipment and machinery installation

• Ensures accurate fit-up during installation.

• Reduces rework and installation errors

• Speeds up the commissioning process

Provides accurate inspection of geometrical parameters such as flatness, verticality, concentricity, and cylindricity

3D Measurement for Installation Assistance

We conduct pre- and post-installation dimensional checks to ensure first-time-right assembly, reducing site rework and project delays.

Ensures accurate fit-up during installation

Reduces rework and installation errors

Speeds up the commissioning process

Uses laser-based 3D metrology to guide equipment and machinery installation

3D Measurement for Installation Assistance

We conduct pre- and post-installation dimensional checks to ensure first-time-right assembly, reducing site rework and project delays.

Ensures accurate fit-up during installation

Reduces rework and installation errors

Speeds up the commissioning process

Uses laser-based 3D metrology to guide equipment and machinery installation

Reference Capture & Benchmarking

• Captures and preserves existing reference points

• Installs new, robust benchmarks tied to absolute coordinates

• Ensures consistency and reliability for all future measurements

Provides accurate inspection of geometrical parameters such as flatness, verticality, concentricity, and cylindricity

Brownfield Reference Capture & Benchmarking

We validate dimensions of existing assets before modification, expansion, or retrofitting to ensure seamless integration with new equipment.

Installs new, robust benchmarks tied to absolute coordinates

Ensures consistency and reliability for all future measurements

Captures and preserves existing reference points

Brownfield Reference Capture & Benchmarking

We validate dimensions of existing assets before modification, expansion, or retrofitting to ensure seamless integration with new equipment.

Installs new, robust benchmarks tied to absolute coordinates

Ensures consistency and reliability for all future measurements

Captures and preserves existing reference points

Alignment & Installation of Critical Components

• Implements streamlined dimensional control for critical alignments during erection.

• Provides real-time guidance throughout the installation process

• Reduces crane time and minimizes shutdown duration

• Ensures precise and accurate installation

Provides accurate inspection of geometrical parameters such as flatness, verticality, concentricity, and cylindricity

Alignment & Installation of Critical Components

We conduct high-quality dimensional inspections during shutdowns to support maintenance, replacement, and realignment within tight outage windows.

Provides real-time guidance throughout the installation process

Reduces crane time and minimizes shutdown duration

Ensures precise and accurate installation

Implements streamlined dimensional control for critical alignments during erection.

Alignment & Installation of Critical Components

We conduct high-quality dimensional inspections during shutdowns to support maintenance, replacement, and realignment within tight outage windows.

Provides real-time guidance throughout the installation process

Reduces crane time and minimizes shutdown duration

Ensures precise and accurate installation

Implements streamlined dimensional control for critical alignments during erection.

Design Validation

We perform dimensional verification during Front End Engineering Design (FEED) and EPC stages to confirm constructability and prevent downstream clashes.

Early identification of dimensional conflicts and clearance issues before execution

Integration of as-is dimensional data for accurate brownfield FEED and EPC planning

Reduction of site rework, delays, and cost overruns through proactive dimensional checks

Improved FEED maturity and EPC execution readiness with data-driven verification

Validation of design intent, interfaces, and tolerances to ensure constructible, clash-free layouts

Design Validation

We perform dimensional verification during Front End Engineering Design (FEED) and EPC stages to confirm constructability and prevent downstream clashes.

Early identification of dimensional conflicts and clearance issues before execution

Integration of as-is dimensional data for accurate brownfield FEED and EPC planning

Reduction of site rework, delays, and cost overruns through proactive dimensional checks

Improved FEED maturity and EPC execution readiness with data-driven verification

Validation of design intent, interfaces, and tolerances to ensure constructible, clash-free layouts