Advancing Digital Transformation Through 3D Insight

For industries operating complex plants and large-scale infrastructure, reliable as-built data forms the backbone of successful planning, expansion, and modernization. SixD’s 3D laser scanning and as-built engineering services deliver detailed digital representations of physical assets—supporting design accuracy, operational clarity, and long-term asset management.

Advancing Digital Transformation Through 3D Insight

For industries operating complex plants and large-scale infrastructure, reliable as-built data forms the backbone of successful planning, expansion, and modernization. SixD’s 3D laser scanning and as-built engineering services deliver detailed digital representations of physical assets—supporting design accuracy, operational clarity, and long-term asset management.

Partnering With India’s Leading Industrial Organizations

SixD is proud to work with some of the nation’s most respected companies, including Reliance Industries Ltd, Tata Steel, MRPL, JSPL, Vardhman, and VSP. These organizations rely on SixD’s engineering expertise to capture, digitize, and interpret critical plant data. Through collaborative engagements, SixD helps these industry leaders strengthen reliability, reduce operational uncertainty, and unlock new engineering possibilities.

Partnering With India’s Leading Industrial Organizations

SixD is proud to work with some of the nation’s most respected companies, including Reliance Industries Ltd, Tata Steel, MRPL, JSPL, Vardhman, and VSP. These organizations rely on SixD’s engineering expertise to capture, digitize, and interpret critical plant data. Through collaborative engagements, SixD helps these industry leaders strengthen reliability, reduce operational uncertainty, and unlock new engineering possibilities.

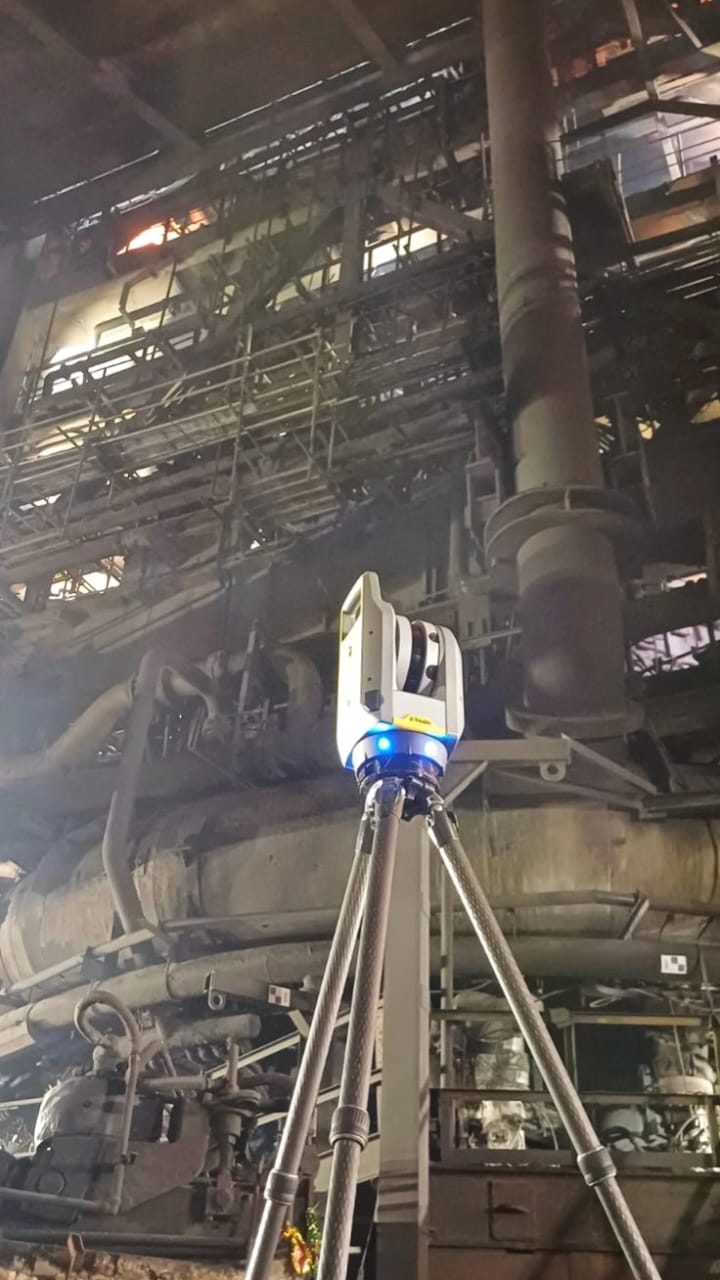

Delivering High-Accuracy Data in Harsh Environments

Laser scanning inside active steel plants is a demanding task, especially in conditions involving extreme heat, elevated humidity, heavy dust, and restricted access areas. At the Cast House of Blast Furnace, SixD successfully executed laser scanning for detailed as-built engineering under such challenging conditions. The team captured high-fidelity point-cloud data while maintaining strict safety protocols and ensuring uninterrupted plant operations.

Delivering High-Accuracy Data in Harsh Environments

Laser scanning inside active steel plants is a demanding task, especially in conditions involving extreme heat, elevated humidity, heavy dust, and restricted access areas. At the Cast House of Blast Furnace, SixD successfully executed laser scanning for detailed as-built engineering under such challenging conditions. The team captured high-fidelity point-cloud data while maintaining strict safety protocols and ensuring uninterrupted plant operations.

Driving Value Across the Engineering Lifecycle

High-quality as-built data enables better planning, reduced rework, and faster decision-making. SixD’s 3D expertise supports revamp planning, clash detection, design validation, and digital-twin development—directly contributing to improved operational efficiency and lifecycle management. With solutions tailored to real-world industrial conditions, SixD continues to help companies turn engineering complexity into clarity.

Driving Value Across the Engineering Lifecycle

High-quality as-built data enables better planning, reduced rework, and faster decision-making. SixD’s 3D expertise supports revamp planning, clash detection, design validation, and digital-twin development—directly contributing to improved operational efficiency and lifecycle management. With solutions tailored to real-world industrial conditions, SixD continues to help companies turn engineering complexity into clarity.