Assessing Large-Capacity Assets at Operational Scale

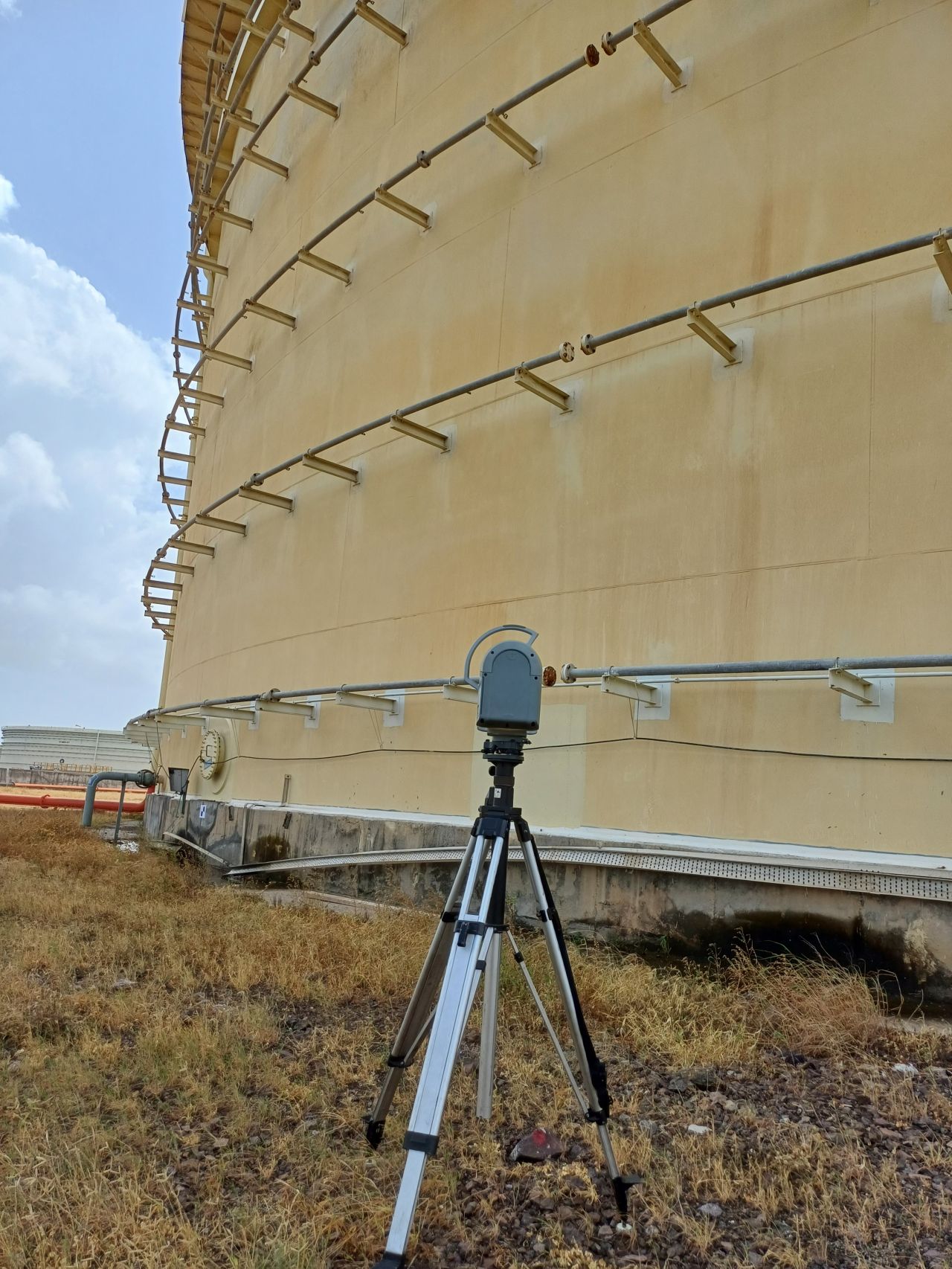

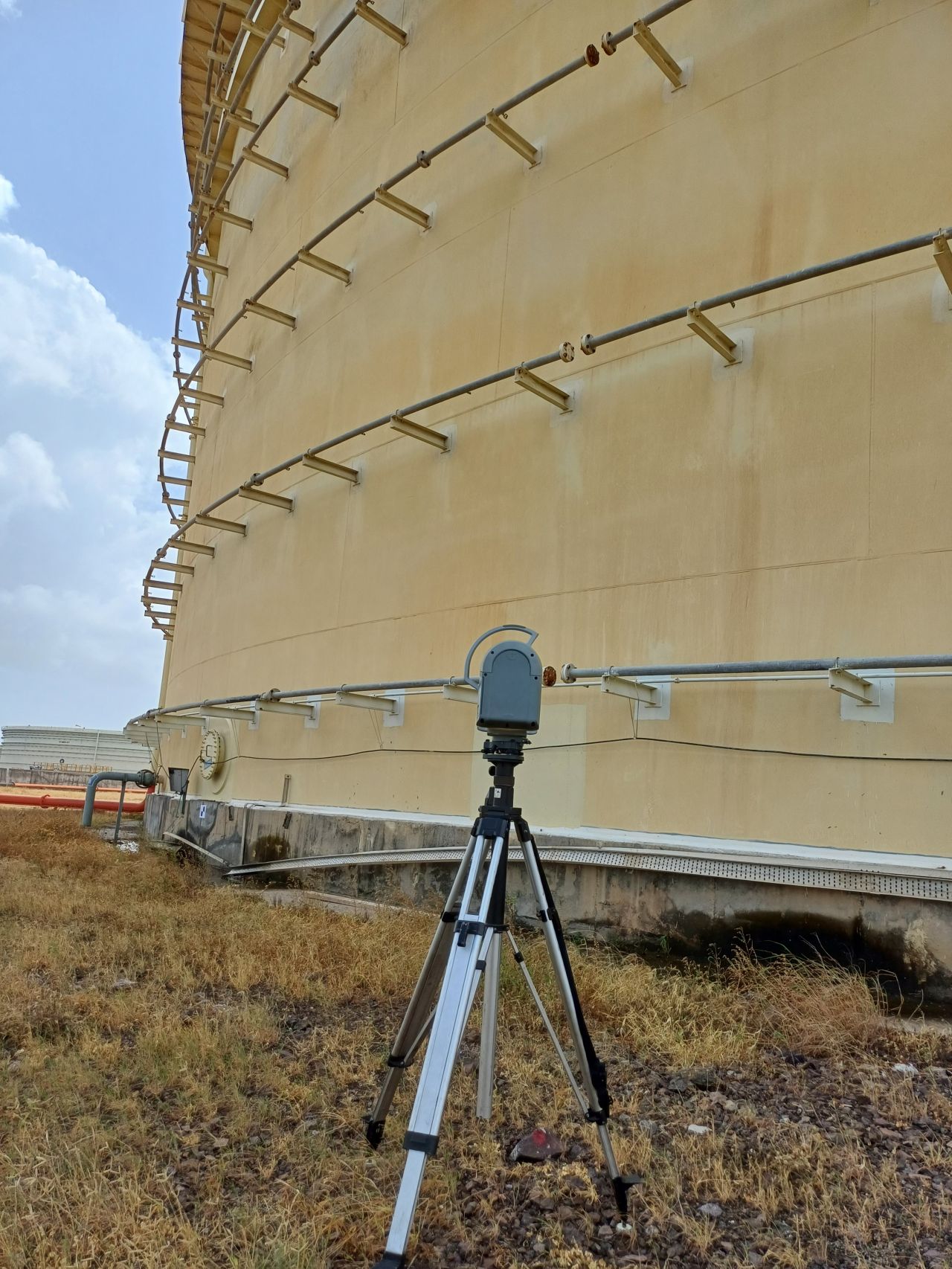

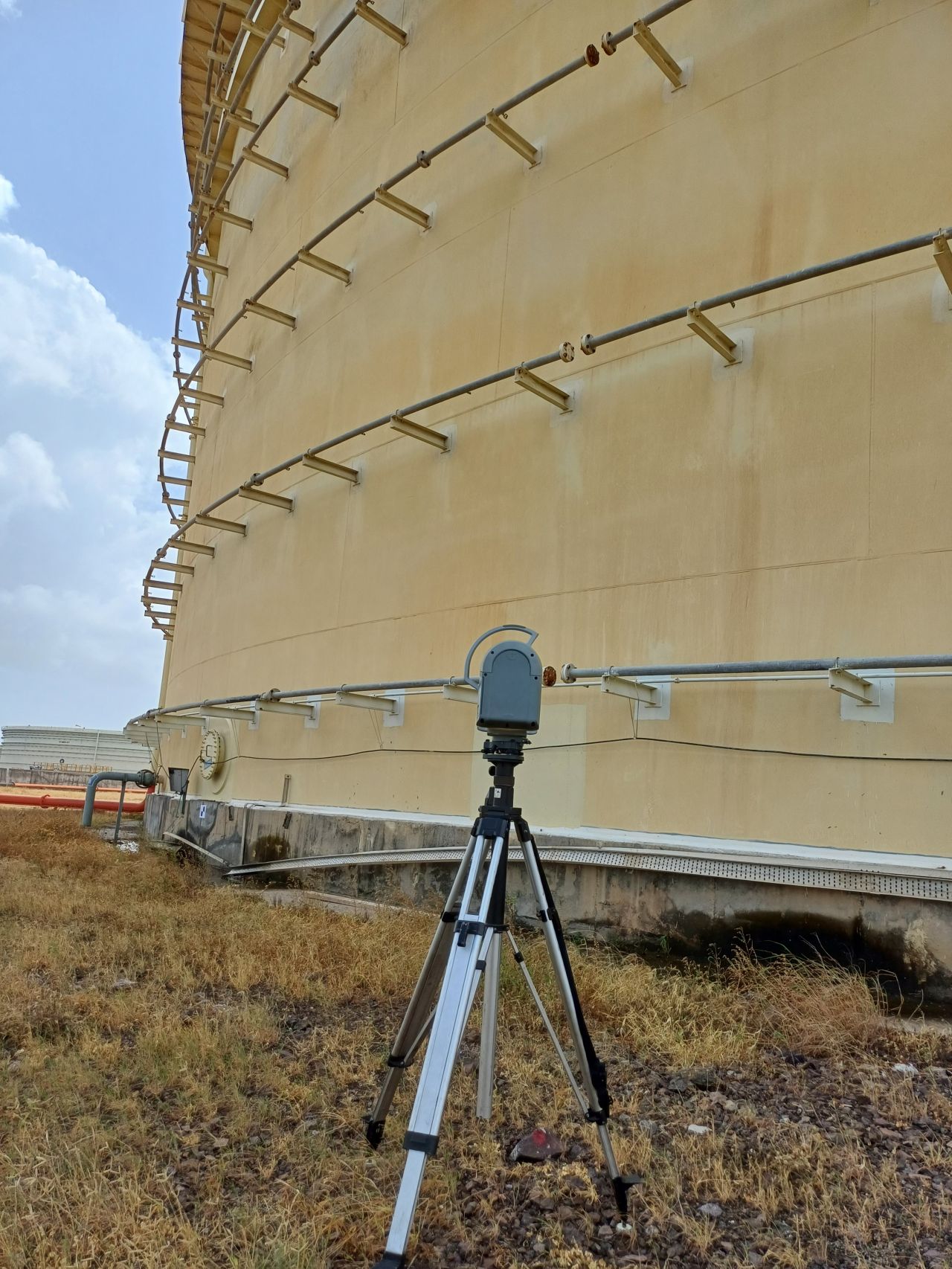

Storage tanks are critical assets in oil, gas, and petrochemical facilities, where structural integrity directly impacts safety and continuity of operations. In this project, SixD completed scanning and inspection of 15 storage tanks, with capacities ranging from 60,000 KL to 120,000 KL, across an active industrial site in the Middle East.

Assessing Large-Capacity Assets at Operational Scale

Storage tanks are critical assets in oil, gas, and petrochemical facilities, where structural integrity directly impacts safety and continuity of operations. In this project, SixD completed scanning and inspection of 15 storage tanks, with capacities ranging from 60,000 KL to 120,000 KL, across an active industrial site in the Middle East.

Standards-Compliant Inspection Approach

All inspection activities were executed in strict alignment with API 653 requirements. Advanced scanning and inspection techniques were used to capture accurate geometric and structural data without disrupting ongoing operations. This approach ensured reliable assessment while maintaining site safety and compliance obligations.

Standards-Compliant Inspection Approach

All inspection activities were executed in strict alignment with API 653 requirements. Advanced scanning and inspection techniques were used to capture accurate geometric and structural data without disrupting ongoing operations. This approach ensured reliable assessment while maintaining site safety and compliance obligations.

Comprehensive Measurement and Analysis Scope

SixD delivered a detailed inspection covering multiple critical parameters, including:

Out-of-roundness and verticality evaluation

Thickness measurements at all critical locations

Shell settlement assessment

Tank floor plate analysis using internal scanning

Floating roof rim-space and gap analysis

Structural integrity checks

Surface distortion and waviness inspection

Drum weld seam overlay evaluation

Each parameter was analyzed to identify deviations, wear patterns, and potential integrity concerns.

Comprehensive Measurement and Analysis Scope

SixD delivered a detailed inspection covering multiple critical parameters, including:

Out-of-roundness and verticality evaluation

Thickness measurements at all critical locations

Shell settlement assessment

Tank floor plate analysis using internal scanning

Floating roof rim-space and gap analysis

Structural integrity checks

Surface distortion and waviness inspection

Drum weld seam overlay evaluation

Each parameter was analyzed to identify deviations, wear patterns, and potential integrity concerns.

Reliable Reporting for Informed Decision-Making

The final inspection report provided the client with clear, actionable insights into the condition of each tank. Verified measurements and structured analysis enabled informed decisions related to maintenance planning, repair strategies, and continued safe operation of the assets.

Reliable Reporting for Informed Decision-Making

The final inspection report provided the client with clear, actionable insights into the condition of each tank. Verified measurements and structured analysis enabled informed decisions related to maintenance planning, repair strategies, and continued safe operation of the assets.