Understanding Point Cloud Data

Point cloud data represents physical environments as millions of spatial points captured through technologies such as LiDAR, photogrammetry, and 3D laser scanning. Each point carries positional coordinates (X, Y, Z) and may include additional attributes like color or intensity. While highly accurate, raw point clouds require further processing before they can be used effectively in engineering workflows.

Understanding Point Cloud Data

Point cloud data represents physical environments as millions of spatial points captured through technologies such as LiDAR, photogrammetry, and 3D laser scanning. Each point carries positional coordinates (X, Y, Z) and may include additional attributes like color or intensity. While highly accurate, raw point clouds require further processing before they can be used effectively in engineering workflows.

Preparing the Data for Modeling

The transformation process begins with preprocessing. This stage focuses on improving data quality and usability through noise filtering, removal of outliers, density reduction, and scan registration. Multiple scan positions are aligned into a single coordinate system, creating a coherent digital representation of the site. These steps ensure performance efficiency and consistency before advanced modeling begins.

Preparing the Data for Modeling

The transformation process begins with preprocessing. This stage focuses on improving data quality and usability through noise filtering, removal of outliers, density reduction, and scan registration. Multiple scan positions are aligned into a single coordinate system, creating a coherent digital representation of the site. These steps ensure performance efficiency and consistency before advanced modeling begins.

Segmentation and Object Classification

Once prepared, the point cloud is segmented to identify and separate individual objects or surfaces such as walls, floors, pipes, or equipment. This can be achieved through manual tagging, rule-based logic, or AI-driven classification using machine learning models. Automated classification significantly accelerates the process while improving consistency across large and complex datasets.

Segmentation and Object Classification

Once prepared, the point cloud is segmented to identify and separate individual objects or surfaces such as walls, floors, pipes, or equipment. This can be achieved through manual tagging, rule-based logic, or AI-driven classification using machine learning models. Automated classification significantly accelerates the process while improving consistency across large and complex datasets.

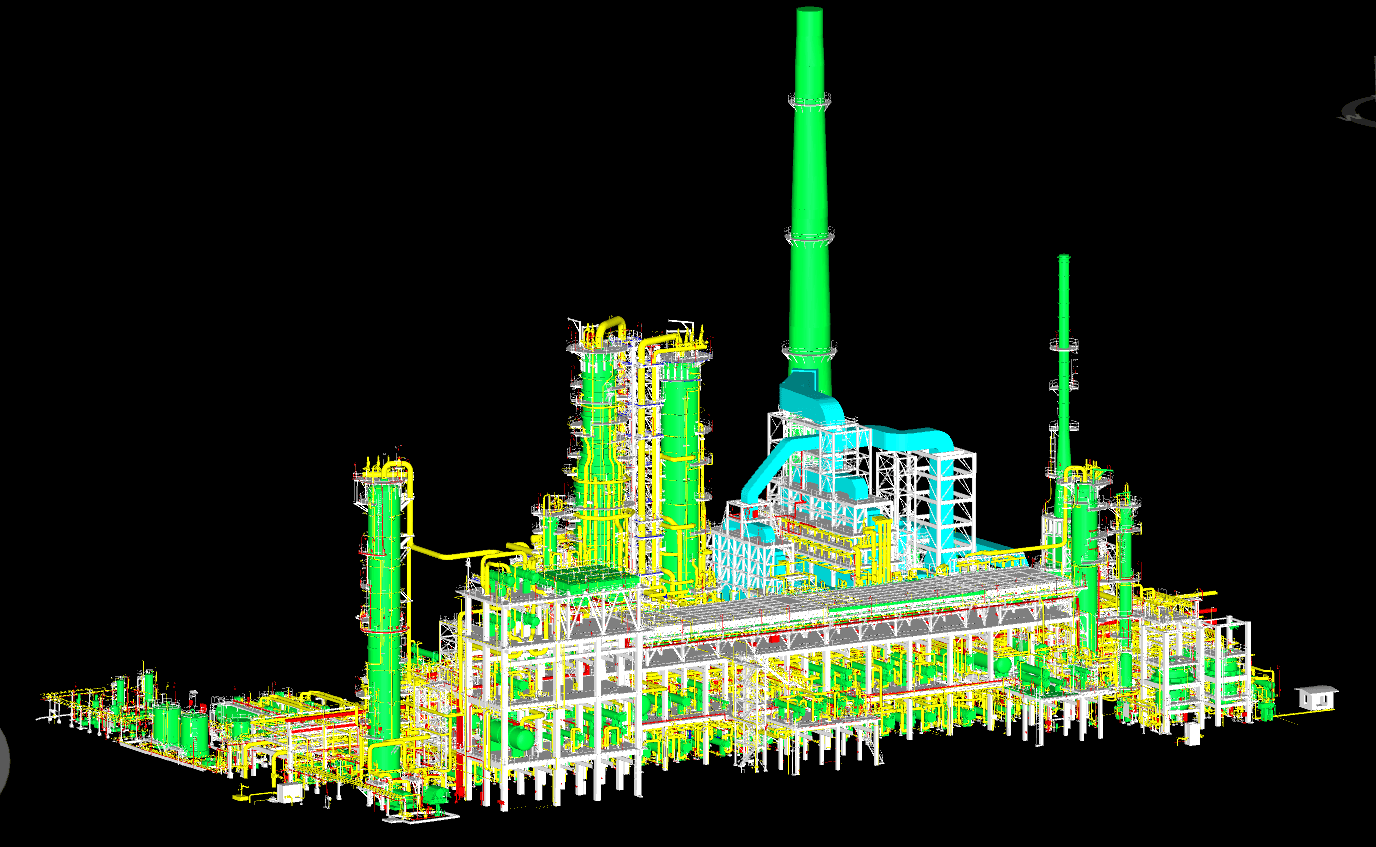

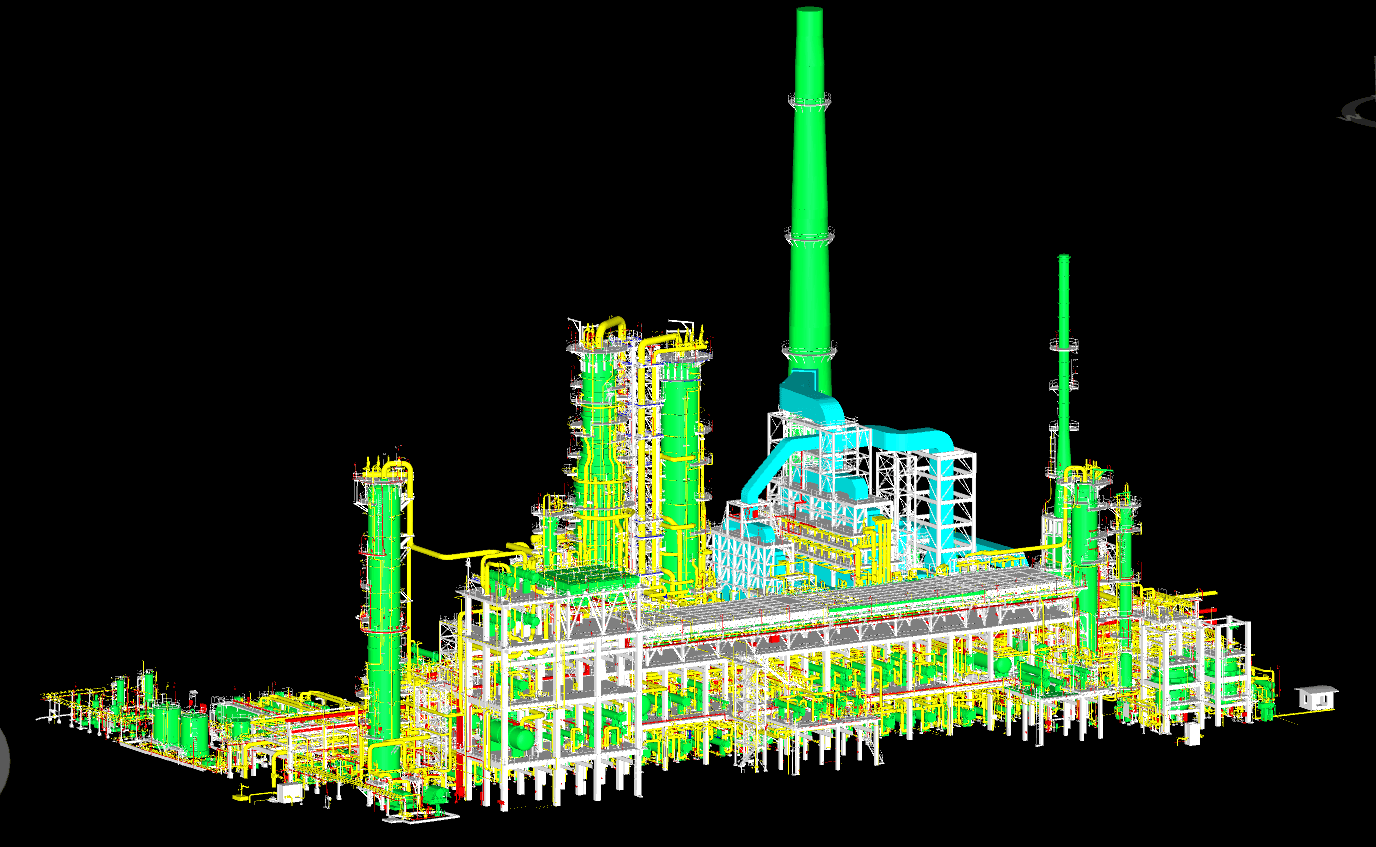

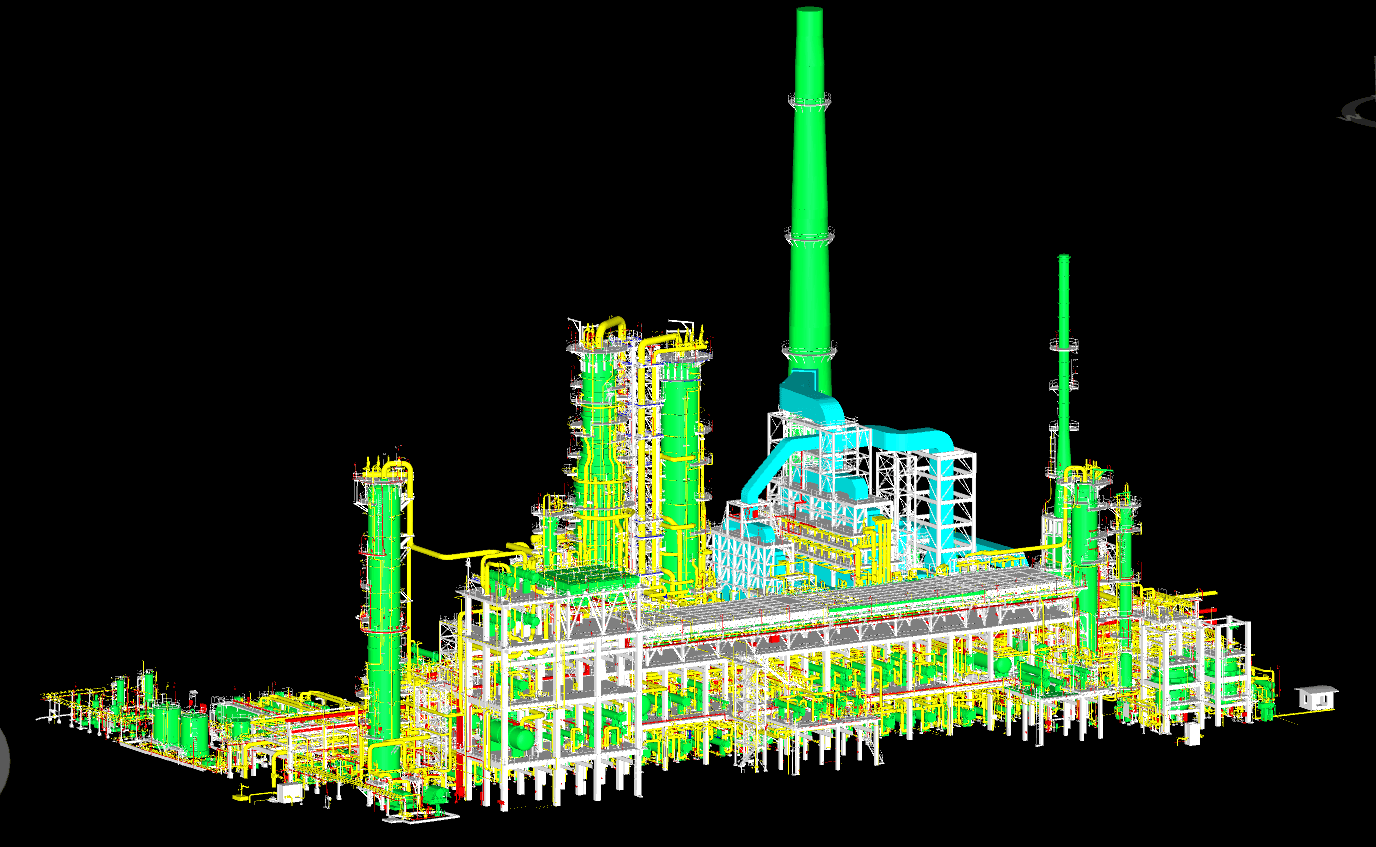

Creating Intelligent, Engineering-Ready Models

The final stage maps reconstructed geometry into intelligent objects for BIM, CAD, or digital-twin environments. Using industry-standard platforms, models are enriched with semantic attributes—transforming static geometry into functional elements like pipes, walls, or structural components. When combined with AI-driven inference, models gain additional intelligence such as material properties, behavior logic, and interoperability across platforms.

Creating Intelligent, Engineering-Ready Models

The final stage maps reconstructed geometry into intelligent objects for BIM, CAD, or digital-twin environments. Using industry-standard platforms, models are enriched with semantic attributes—transforming static geometry into functional elements like pipes, walls, or structural components. When combined with AI-driven inference, models gain additional intelligence such as material properties, behavior logic, and interoperability across platforms.